Measurement Systems

This measurement system is used in combination with sensors.

You can choose from measurement, threshold setting, normal monitoring, and even machine learning, depending on your needs.

Dedicated Measurement System

List of measurement systems dedicated for piezoelectric load sensor "PiezoBolt".

EdgeSenses

This is the Edge device which supports transffering data wirelessly.

Designed for real-time monitoring in mass production:; this conpact device features a built-in PC.

EdgeSenses is the measuring system with measurement/evaluation software; the installation of sensors other than PiezoBolt is possible.

| Input Channels | Basic 1 channel Up to 6 channels(option) |

|---|---|

| Output channel | Standard |

| Reference channel | Standard |

| Universal channel | Option |

| Built-in software | Equipped with dedicated software ・Measurement/Evaluation Software:Consenses MDS ・Evaluation Module:Smart Evaluator ・Data Transfer Module:connectAI ・Report Module:Report Tool |

DeveloperSenses(The new version is coming soon)

This measurement system is suitcase-shaped and easy to carry.

It is suitable for use in research and prototyping because it can be easily executed from measurement to evaluation.

| Input Channels | Basic 1 channel Up to 6 channels(option) |

|---|---|

| Output channel | Option |

| Reference channel | Standard |

| Universal channel | Option |

| Built-in software | Equipped with dedicated software ・Measurement/Evaluation Software:Consenses MDS ・Evaluation Module:Smart Evaluator ・Data Transfer Module:connectAI ・Report Module:Report Tool |

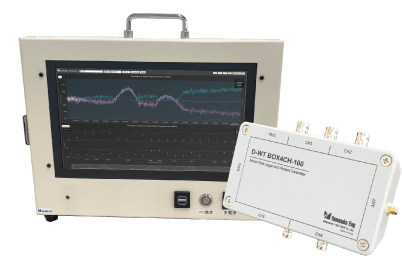

YMC with D-WT

Equipped with a unique evaluation program, it handles everything from measurement to evaluation and control.

All-in-one measurement and control unit

It is equipped with measurement instruments, management PC, touch screen, and all devices necessary for measurement.

Exclusive customized software

Designed for press working.

Features data collection, analysis, and visualization capabilities.

Outputs signals to equipment.

Software can be customized to meet your needs.

| Input Channels | 4 channels |

|---|---|

| Output channel | Standard |

| Reference channel | Option |

| Universal channel | Standard |

| Built-in software | Equipped with dedicated software |

Monitoring system with machine learning function

MMM(MuratecMoldingMonitor)

A single unit of this system can simultaneously measure up to 20 channels of sensors.

By comparing the data of abnormalities between each sensor, it is possible to pinpoint the cause of the abnormality. In addition, by learning from the abnormal data, it is possible to detect signs of abnormalities and defective products during mass production.

Details,You can click here(Moves to the website of the manufacturer, Muratec Mechatronics, Inc.)

To use PiezoBolt with MMMDedicated charge amplifierRequired.

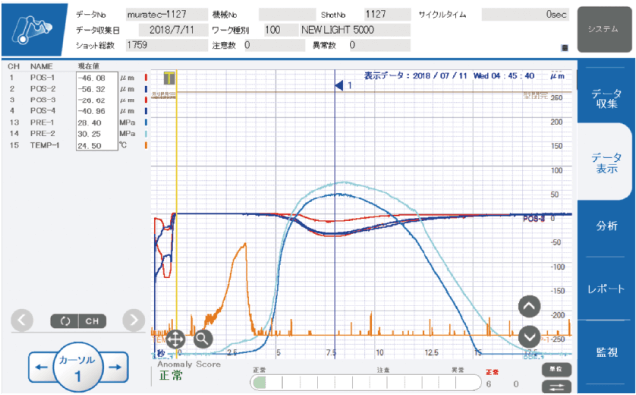

Real-time monitoring

By learning star data (good conditions), score judgments are made for each shot. This enables the occurrence and prediction of abnormalities.

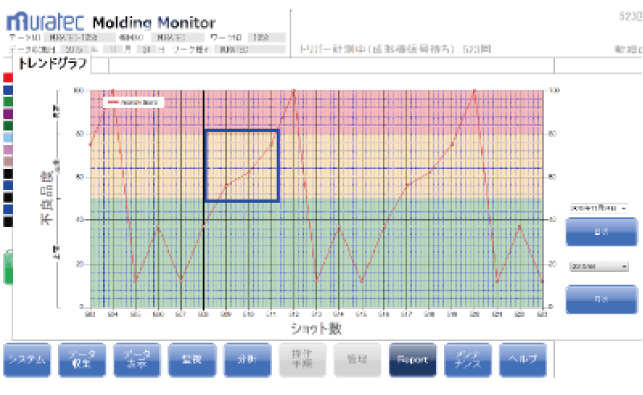

Visualization of production status

Production status within a certain time period can be checked at a glance by dividing it into three areas: normal, alert, and abnormal.

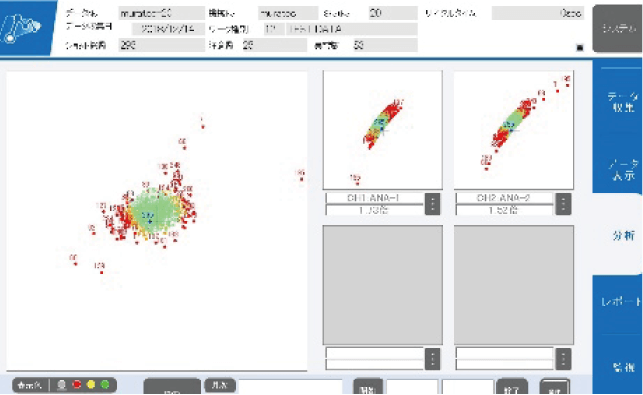

Confirmation of distribution for each sensor

The accuracy of the data to be trained can be improved by checking the distribution of results for each shot of each sensor that is measured at the same time.