Detecting anomaly of die casting

This case study is excerpted from the IVI (Industrial Value Chain Initiative), Business Scenario WG activities.

Issue

Casting nests occasionally occur in aluminum die casting production

- Casting cavities occur due to differences in casting machines, even though they are produced under the same conditions.

- We don't have the true cause of what is causing the casting nests.

Solution

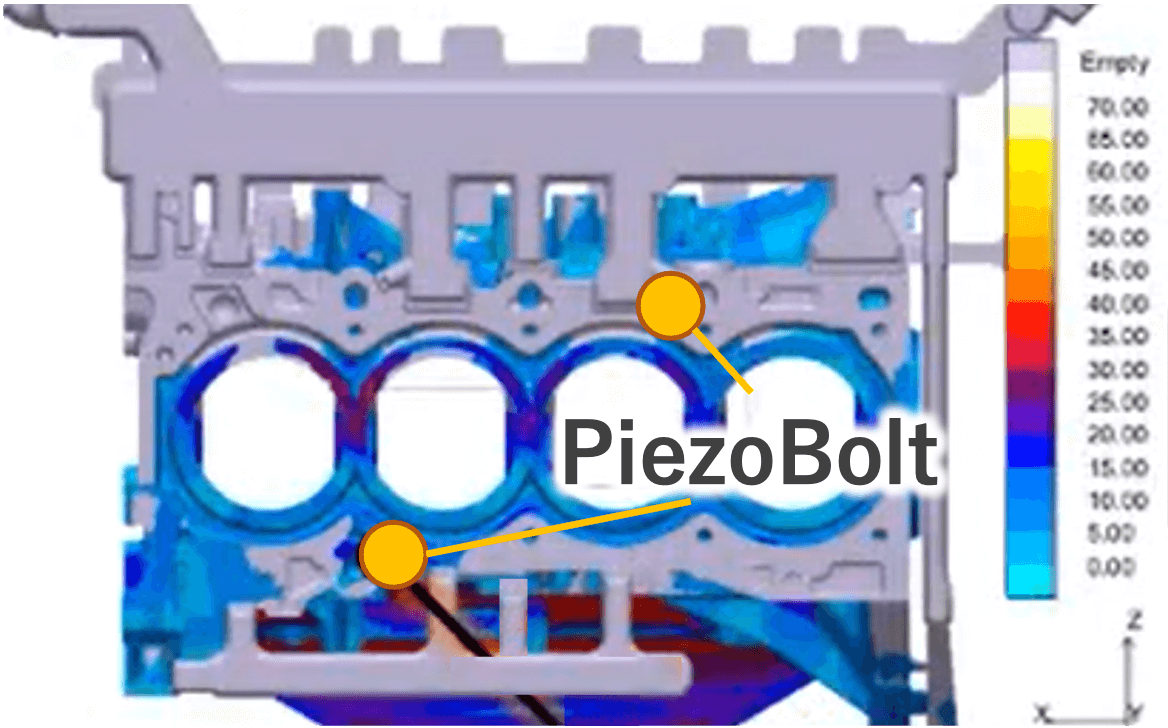

A piezoelectric load sensor, PiezoBolt, was installed to detect the pressure applied to the extrusion pin and measurements was taken.

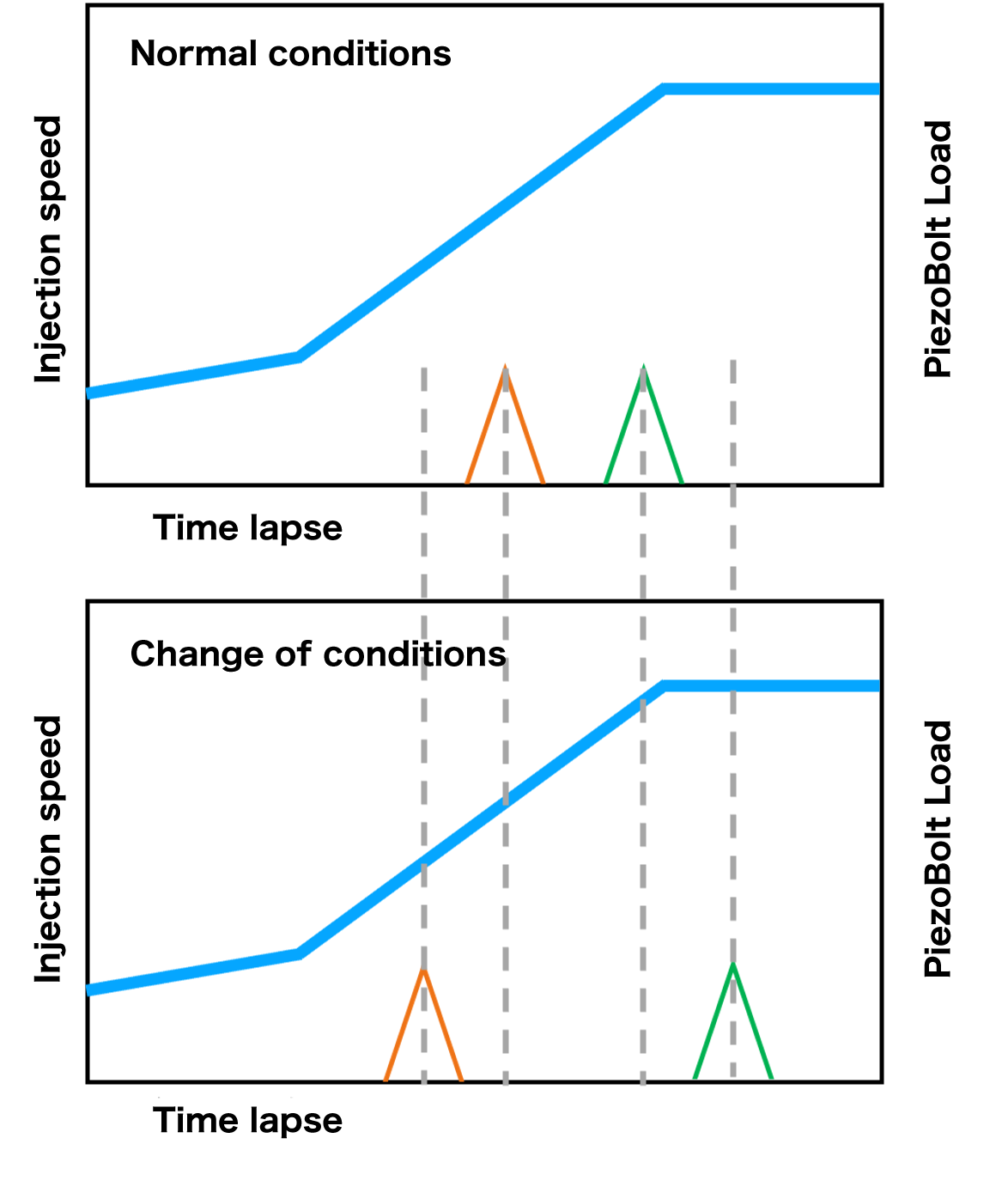

As a result, it was found that differences in molten metal temperature and die temperature caused discrepancies in the timing of pressure buildup. The timing discrepancy also changed the way molten metal flowed, and the cause of casting cavities was identified as the inability to release internal gases.

Result

Optimization of casting conditions to reduce defect rate

- We were able to elucidate the mechanism of casting nest generation.

- Casting conditions were optimized and the defect rate was reduced.

Customer Testimonials

We have several casting machines, and it was good that we could easily expand. In the future, we plan to expand the system to other facilities to create a mechanism to improve product as well as quality.

Industry: Automobile manufacturer

Products Used:

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting