Detecting adhesion of scrap

Issue

Scraps are adhered during the punching process of motor cores

- Existing adhension of scrap sensors alone are unable to detect them, causing defective products to flow out.

- To prevent the outflow of defective products, we are using 100% inspection, which is costly.

Solution

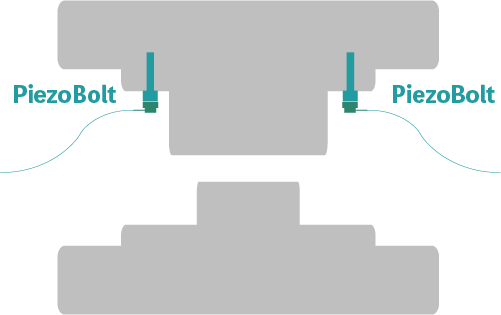

A piezoelectric load sensor "PiezoBolt" was installed behind the punch for measurement.

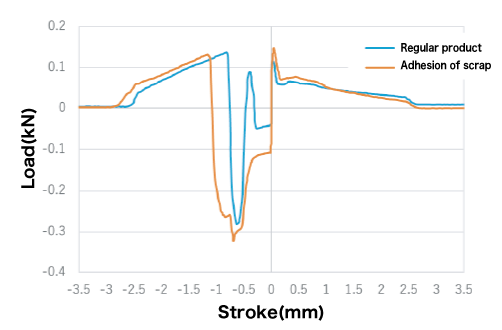

As a result, it was found that the load trend applied to the PiezoBolt differs greatly between normal operation and when adhension of scraps occur. By setting the forming load data to a threshold value, we have established a system that sends out a warning/stop signal when the data deviates from the threshold value. This prevents the outflow of defective products.

Result

Detects defective products due to adhension of scrap

- It was able to detect anomalies that could not be detected by the adhension of scrap sensor alone.

- Preventing the outflow of defective products has led to cost reductions by eliminating the need for full inspections.

Customer Testimonials

The product was 0.2 mm thin, and we were concerned about whether abnormalities could be detected, but we were reassured that the data could be measured accurately. More accurate detection was achieved by using the sensor in conjunction with adhension of scrap sensor.

Industry: Automobile parts manufacturer

Products Used:

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting