Die breakage detection

Issue

Premature die breakage occurs

- Premature breakage of die spacers, short life of dies, and failure to prevent defective products.

- Various measures have been taken, but no solution has been reached because the cause is not known.

Solution

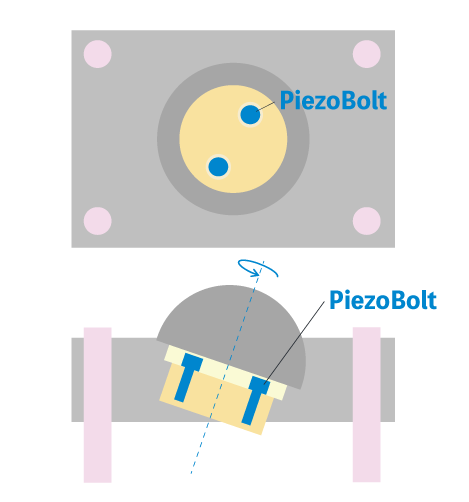

Two bolts that fasten the die to the spacer were replaced with the piezoelectric load sensor "PiezoBolt" to visualize and evaluate the forming conditions.

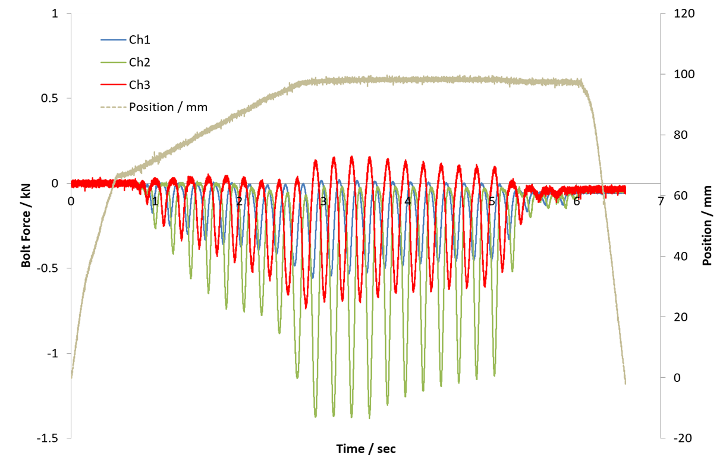

As a result, it was confirmed that a large tensile load was applied to the PiezoBolt from the middle of the forming process under conditions that lead to early failure. Since it was thought that the tensile load was generated by the deflection of the spacer, we changed the shape of the pressure receiver and the tensile load was no longer generated.

Result

Identifies causes of die breakage and improves die life

- By visualizing the load conditions of the spacer and the elastic deformation, it was possible to quantitatively assess the risk of a spacer breach.

- Identification of conditions that lead to premature breakage and predictive detection of spacer breakage before it occurs.

- The cause of spacer breakage was identified and measurement data were utilized in the design to improve die life.

Customer Testimonials

I was attracted by the fact that the load sensor is a bolt-type load sensor that can be fastened directly to the bolt holes of the spacer where the problem occurs. Since there is no need for additional processing, I thought it would be possible to detect the cause of abnormalities in various processes other than the same die.

Industry: Automobile parts manufacturer

Products Used:

- Piezoelectric Load Sensors PiezoBolt

- DeveloperSenses

- Wire type linear sensor

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting