Foreign object strike detection

Issue

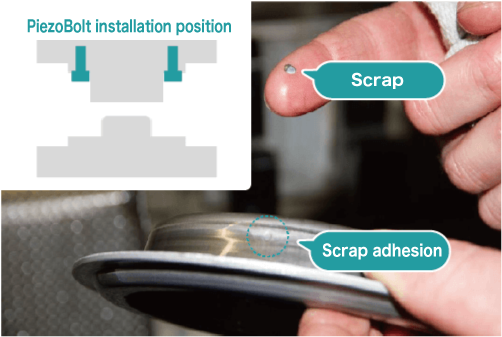

Defects occur due to small scrap strike marks in the plate drawing process

- Defects are caused by hammering in scrap as small as 1 to 2 mm.

- Detection is done by image inspection and the bottom dead center sensor, but 100% detection is not possible.

- Labor costs are high due to the possibility of defective products leaking out, as all inspections are conducted.

Solution

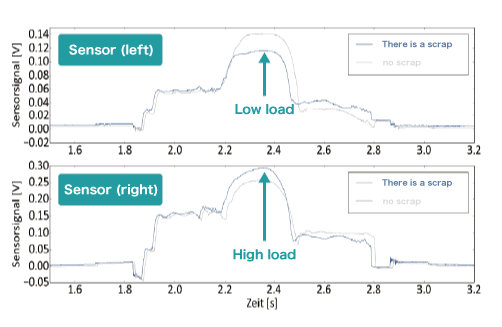

Two bolts for fixing the die were replaced with the piezoelectric load sensor "PiezoBolt" to monitor load fluctuations.

As a result, it was found that there was a difference in the load applied to the left and right bolts (eccentricity) when scrap was sandwiched between them. By creating a system that can detect the same regardless of the size of the scrap and by determining a threshold value and creating an alarm to alert the operator if a defect occurs, we were able to identify defective products caught between the scraps and eliminate all inspections.

Result

Eliminate all inspections by detecting the launch of foreign objects

- It is now possible to detect when impurities such as burrs and scrap are introduced.

- By quantifying eccentricity conditions, the frequency of burr generation can be improved and detection can be made before burrs affect quality.

- Reliable detection of foreign object strikes eliminates the need for a full inspection.

Customer Testimonials

We were attracted to the fact that the high sensitivity of the system enables us to detect burrs before they cause product defects. Also, by monitoring the entire process in real time, we are now able to understand the cause of any abnormalities that may occur.

Industry: Electronic component manufacturer

Products Used:

- Piezoelectric Load Sensors PiezoBolt

- DeveloperSenses

- Wire type linear sensor

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting