Detecting punch breakage

Issue

Punch damaged in stamping out forming

- Failure to notice when punches are damaged, resulting in mass production of defective products.

- Although spot checks are conducted, they sometimes slip through the cracks.

- Secondary damage to dies caused by punch debris.

Solution

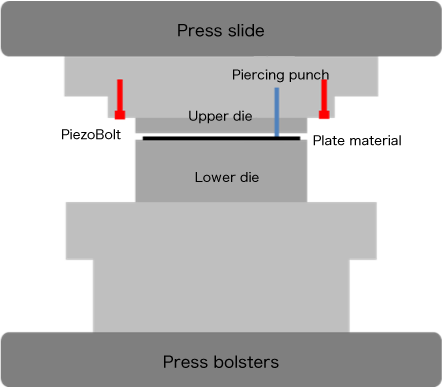

The four bolts (front, back, left, and right fasteners) on the holder used to secure the die to the die plate were replaced with the piezoelectric load sensor "PiezoBolt" and monitored for about one month.

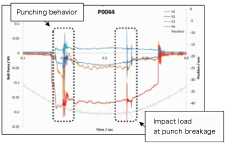

As a result, we were able to confirm that the force applied to the product changed slightly over the course of one month. Since we were also able to measure the impact load at the time of punch breakage, we were able to prevent the production of defective products by establishing a system to inform us of any signs of abnormalities in the punches as soon as they occurred.

Result

Realize performance evaluation of lubricants to improve quality

- No more punching debris, resulting in a cost savings of 2 million yen per month.

- A system that immediately notifies the company if a punch is found to be defective, thus stopping the continuous production of defective products.

- Minimizing the number of people on the production floor because what is happening on the production floor can now be seen in the office and at other locations.

Customer Testimonials

Because of its high sensitivity, the impact behavior at the time of punch breakage could be detected even when mounted a short distance away from the punch, so there was no need for additional machining for sensor mounting.

Industry: General consumer electronics manufacturer

Products Used:

- Piezoelectric Load Sensors PiezoBolt

- EdgeSenses

- Wire type linear sensor

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting