Visualization of press forming

Issue

Mass production presses cause many product defects

- Good products were produced on the prototype press, but even after transferring the entire die set to the mass production press and performing forming under the same conditions as on the prototype press, no good products were produced.

- Not knowing what causes defects to occur causes many defects to occur.

Solution

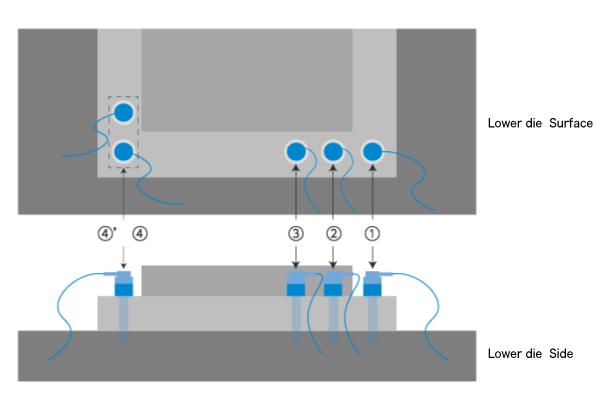

PiezoBolt piezoelectric load sensors were embedded in the cushion pins of the press to monitor changes in the compression load on each pin during forming.

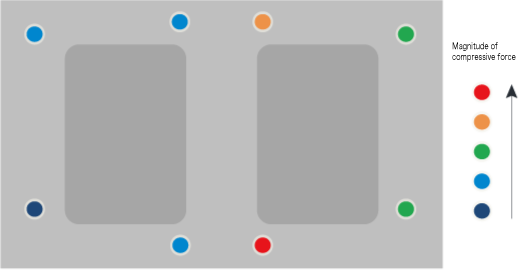

As a result, it was confirmed that there was a significant difference in the load distribution applied to each cushion pin between the prototype press and the mass production press.

We were able to produce good products by adjusting the shims and load distribution to match the forming conditions of the prototype press.

Result

Visualization of press equipment conditions and identification of causes of defects

- Visualization of the equipment status of prototype and mass production presses has enabled us to understand the phenomenon of defective presses.

- Real-time monitoring of equipment conditions enables immediate countermeasures to be taken on the spot when waveforms close to the conditions for defects to occur are detected.

- Visualization of individual differences among facilities has made it possible to create optimal forming conditions for each facility, rather than forming under uniform conditions for all facilities.

Customer Testimonials

Through the demonstration, we were able to visualize minute differences in press loads as numbers, and we felt that monitoring of press equipment movements, which had been invisible until now, would be realized.

Industry: Automotive parts manufacturer

Products Used:

- Piezoelectric Load Sensors PiezoBolt

- EdgeSenses

- Wire type linear sensor

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting