Life prediction by punch abrasion

Issue

Poor product quality due to punch abrasion, no means to visualize die damage

- As punches wear out, damage to surrounding dies increases and die life varies.

- Unable to visualize subtle changes in the state of the punch, so no countermeasures can be taken.

- As a temporary workaround, constant replacement of both punches and dies is being performed, but at a high cost.

Solution

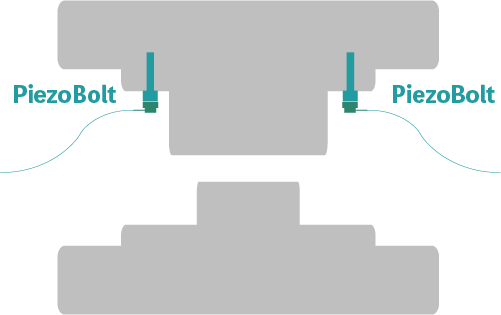

PiezoBolt" piezoelectric load sensors were installed at two locations in front and behind the plate where the punch is fixed to measure the load applied to the plate.

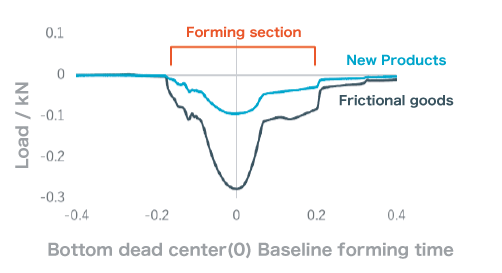

As a result of comparing the loads generated by new punches and worn punches, it was found that the peak load at the bottom dead center of worn punches was three times greater than that of new punches. Based on these results, a threshold value was set, and an alarm was issued and equipment stopped when the threshold value was exceeded, thereby preventing damage to the surrounding dies. At the same time, the life of the punch itself was also improved.

Result

Real-time monitoring of punch and die conditions

- Visualization of punch status during forming prevents defective products from occurring.

- The condition of the punches and dies allowed us to set appropriate replacement timing and reduce lost costs.

Customer Testimonials

The installation location was difficult and sensing was not possible, but the piezoelectric load sensor "PiezoBolt" was appealing because it could be used simply by replacing the existing bolts. Another decisive factor in the decision to introduce the PiezoBolt was its ability to perform high-precision measurements by simply controlling the tightening torque, without the need for calibration.

Industry: General consumer electronics manufacturer

Products Used:

- Piezoelectric Load Sensors PiezoBolt

- EdgeSenses

- Wire type linear sensor

Case Study List

- Detecting tool crack propagation

- Die breakage detection

- Life prediction by punch abrasion

- Lubricant Evaluation

- Detecting punch breakage

- Foreign object strike detection

- Detecting adhesion of scrap

- Visualization of press forming

- Equipment maintenance of presses

- Failure detection of cutting tools

- Detecting anomaly of die casting