Release Date:2024/09/03

What is a Die Set? – From Structure and Types to the Latest Smart Die Sets with Defect Detection Features

A Die Set is a fixture used to mount plastic forming dies onto press machines, ensuring the correct positional relationship between the upper and lower dies.

At Yamanaka Eng, we offer a variety of die sets, including:

- Enclosed Die Set

- High-Precision Die Set: Enables the production of high-precision forged products, even with older press equipment.

- Smart Die Set: Equipped with defect detection capabilities.

In this article, we will provide an overview of die sets and introduce the specifications and features of our various die sets.

Contents

What is a Die Set?

A Die Set is a fixture used to mount plastic forming dies onto press machines, ensuring the correct positional relationship between the upper and lower dies.

By manufacturing a standard die set that can be commonly used, it becomes possible to perform plastic forming on various products and processes by only replacing specific parts, such as the forming dies.

Key Considerations:

- Eccentricity Accuracy: Ensuring accurate eccentricity is critical.

- Poor processing or assembly accuracy can make it difficult to maintain the concentricity of the upper and lower dies, leading to negative effects on both the dies and the products.

Die Set Components

A Die Set is composed of the following components:

- Forming Section: Interacts with the material to shape the product.

- Mounting Section: Attaches the forming section to the press machine.

- Pressure Receiving Section: Reduces the pressure applied to the forming section and transfers it to the press machine itself.

Each component is designed and manufactured to have a simple shape whenever possible..

Types of Die Sets

There are various types of Die Sets, which are selected based on the required stiffness, accuracy, and application.

Stiffness

- Steel Type: Offers high rigidity and durability.

- Aluminum Alloy Type: Lightweight and suitable for applications requiring less stiffness.

Accuracy

- Die Sets differ in the fitting methods of guide posts and guide bushes, which affect their precision.

Application

- There are many types of Die sets designed for specific purposes, such as trimming.

- Die Sets can be applied across various industries, but the selection should be made by considering factors such as price, functionality, and quality.

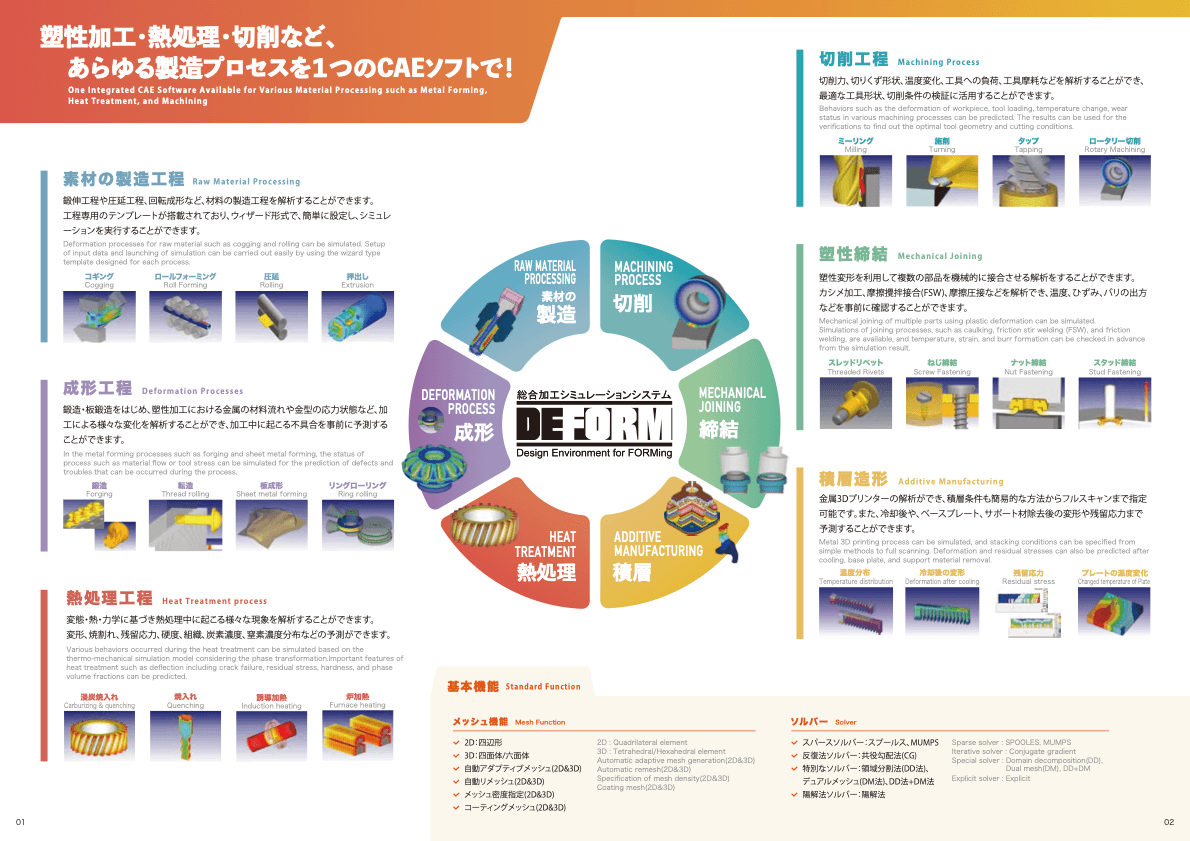

Enclosed Die Set

Strictly speaking, an Enclosed Die Set refers to a “Die Set for fully enclosed forging”, which is equipment used to form material by closing the upper and lower dies and pushing the material within the dies.

In this method, the metal dies must remain closed at all times, enduring the forging pressure that attempts to open them. This means the clamping pressure must be greater than or equal to the opening pressure, but this clamping pressure adds load to the press, reducing its forging ability.

Key Considerations:

- If the clamping force is too strong, the forging power will be reduced.

- If the clamping force is too weak, the dies may open, leading to burr formation and difficulty in ensuring the accuracy of forged products.

It is noteworthy that the forming load and the force attempting to open the dies are not constant but fluctuate during the forging process. Ideally, the dies should be closed with a force approximately 20-40% greater than the opening pressure.

Features of Closed Forging

The most notable feature of Closed Forging is that it allows for burr-free forming and enables material forming in directions differing by 90 degrees from the movement direction of the press..

There are two types of closed forging methods, each with distinct movements:

- Semi-Closed Forging: A method where the material is pressed from one side.

- Full-Enclosed Forming: A method where the material is pressed simultaneously from both the top and bottom.

Each method has its unique characteristics.

Semi-Closed Forging

In Semi-Closed Forging, the upper and lower dies close just before reaching the bottom dead center. Afterward, the material is forged by pressing it from one side using a forming pin.

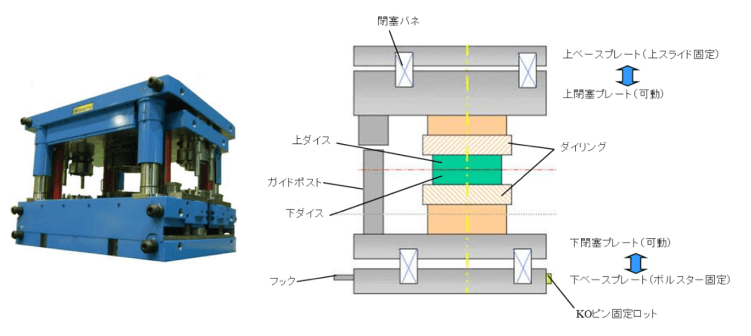

Full-Enclosed Forging

In Full Enclosed Forging, both the upper and lower dies close just before reaching the bottom dead center. The material is then pressed and forged simultaneously using upper and lower forming pins.

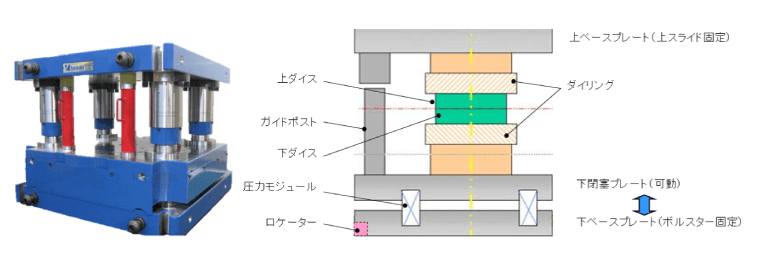

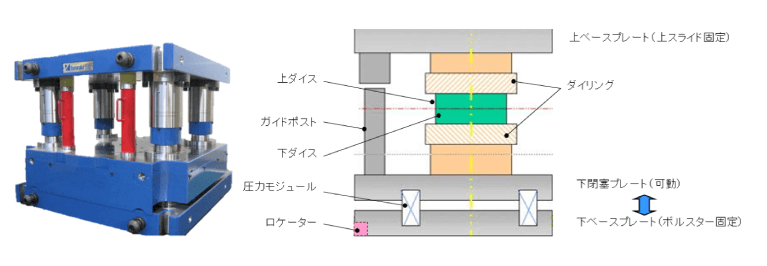

A Full-Enclosed Die Set consists of:

- Upper and Lower Plates: Hold the upper and lower forming pins.

- Upper and Lower Movable Plates: Secure the dies for closing.

- Guide Posts: Ensure alignment and stability.

The Full-Enclosed Die Set is composed of four plates arranged vertically and guide posts.

Differences Between Normal Die Set and Closed Die Set

A Normal Die Set consists of two plates (upper and lower) and a guide post. In contrast:

- A Semi-Closed Die Set includes the die and punch on the press side, along with a locked plate, totaling three plates.

- A Fully Enclosed Die Set consists of four plates arranged vertically.

Key Considerations:

- Precise fitting of the upper and lower dies at the designated position is crucial.

- Concentricity, phase, and gradient must be controlled with high accuracy.

- Clearances for guide posts and fitting parts are set with a precision of 10 microns, and lubrication must always be applied to the fitting surfaces.

Disadvantages:

- Closed Die Sets are heavier due to the additional plates, requiring consideration for overload (e.g., allowable loads for press machines and cranes).

- For normal Die Sets, the accuracy of forged products depends on the press machine’s precision, with initial accuracy being important but aging effects being less of a concern.

- Closed Die Sets demand much higher accuracy in the dies compared to normal Die Sets, making precision in each part critical.

Spring-Loaded Die Set and Hydraulic Die Set

The required closing force varies depending on the shape of forged products. There are two methods to achieve clamping force:

Spring-Loaded Die Set:

- The closing force increases gradually as the spring compresses, reaching maximum pressure at the bottom dead center.

- Suitable for processes requiring high clamping pressure only at the end of the pressing stroke.

- Requires larger plates to accommodate multiple springs.

- Operates mechanically, offering the advantage of not requiring electricity.

Hydraulic Die Set:

- Produces high pressure from the beginning. Making it suitable for products requiring strong clamping force from the start.

- Requires careful management due to the use of oil pressure and needs electricity.

High Precision Die Set

Recent developments in high-precision forged products using advanced press equipment have been reported. However, the high cost of such equipment makes it challenging for small and medium-sized enterprises with older press equipment to adopt these technologies.

Our High-Precision Die Set offers a solution by achieving dimensional accuracy equal to or greater than that of cold forging processes using the latest high-precision equipment, while utilizing existing press equipment.

Key Features:

Dimensional Accuracy:

- Minimizes deviations in forged products while reducing the impact of press operations.

Advanced Technologies:

- Eliminates the effects of press operations.

- High-precision positioning technology.

- Zero-clearance forming technology.

These technologies are independent and can be partially applied to improve existing processes.

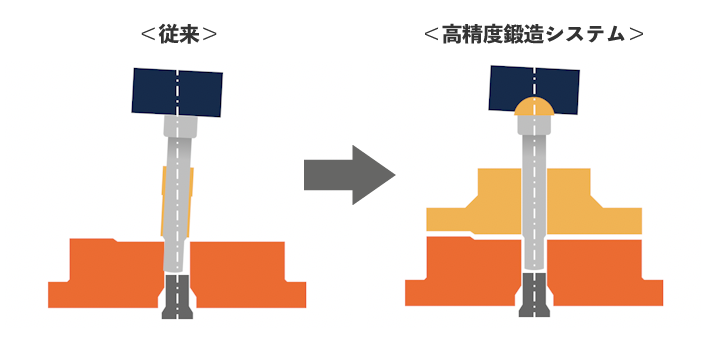

Differences Between Normal Die Set and High-Precision Die Set

A Normal Die Set is typically structured with a punch that follows the movements of the upper plate on the press machine.

On the other hand, our High Precision Die Set incorporates a spherical seating system to automatically adjust the angle. This system ensures the interface remains horizontal, reducing the influence of lateral and rotational motions caused by the press machine. This significantly improves the concentricity of the workpiece.

In a normal Die Set, the concentricity and verticality of forged products are determined by fitting the punch guide into the lower die. However, the gap between the fitting part and the clearances of the punch guide and punch can greatly affect the concentricity and verticality.

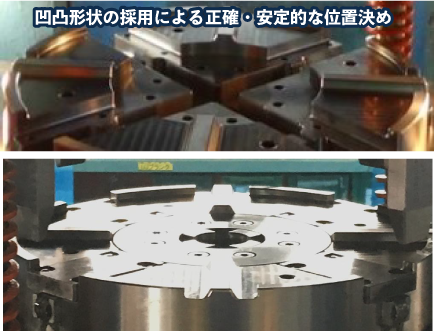

Our High-Precision Die Set features a convex-concave structure designed on the outer upper surface to ensure the concentricity of the upper and lower dies. This structure ensures zero clearance between the positioning spot and the punch, preventing debris from getting stuck. Additionally, it is crucial to always apply lubricant to the zero-clearance part of the punch to maintain optimal performance.

Disadvantages:

- The punch guide is larger, and the upper die must contact the lower die (kissing) before the forming process begins. This requires careful attention to the relationship with the transfer device

However, our High-Precision Die Set has a disadvantage in having a huge punch guide, and it is necessary to bring the upper die into contact with the lower die before the forming process, which requires careful attention to the transfer device.

Smart Die Set

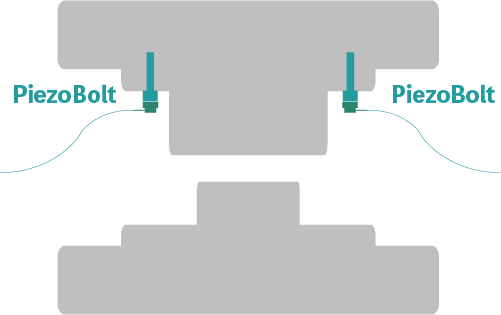

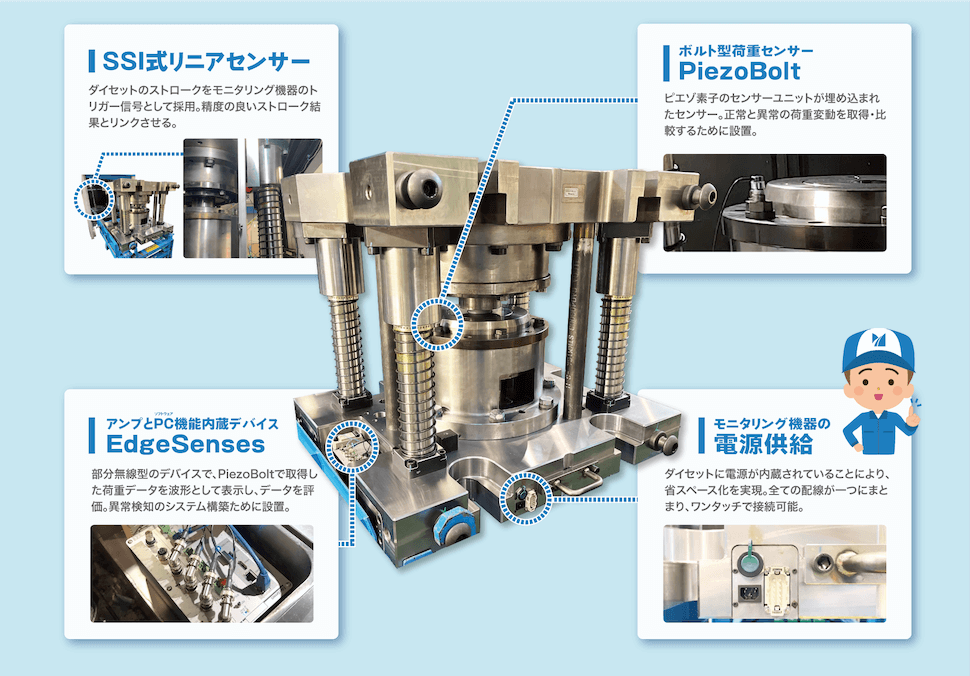

Our Smart Die Set integrates the wiring of sensors (PiezoBolt) and peripheral devices within the die set itself.. This Die Set is designed to detect abnormalities during forging processes.

※What is the Bolt Piezoelectric Load Sensor “PiezoBolt”?

PiezoBolt is the load sensor with an embedded sensor unit using a piezoelectric element inside the bolt. It is capable of measuring minute load changes by leveraging the piezoelectric effect, which generates voltage when force (pressure) is applied.

For more detailed information, please click the link below.

Key Features:

- Enhanced Safety: Internal wiring eliminates the risk of disconnection or damage, ensuring high safety.

- Simplified Setup: No need for complex wiring installation, and power can be supplied with a single touch, significantly reducing setup time.

- Remote Monitoring: Enables real-time monitoring not only on-site but also remotely from distant locations.

Conclusion

We hope you found our article helpful. Thank you for taking the time to read it!

Yamanaka can design and develop Die Sets tailored to your specific needs. If you have any questions or concerns, please feel free to contact us.