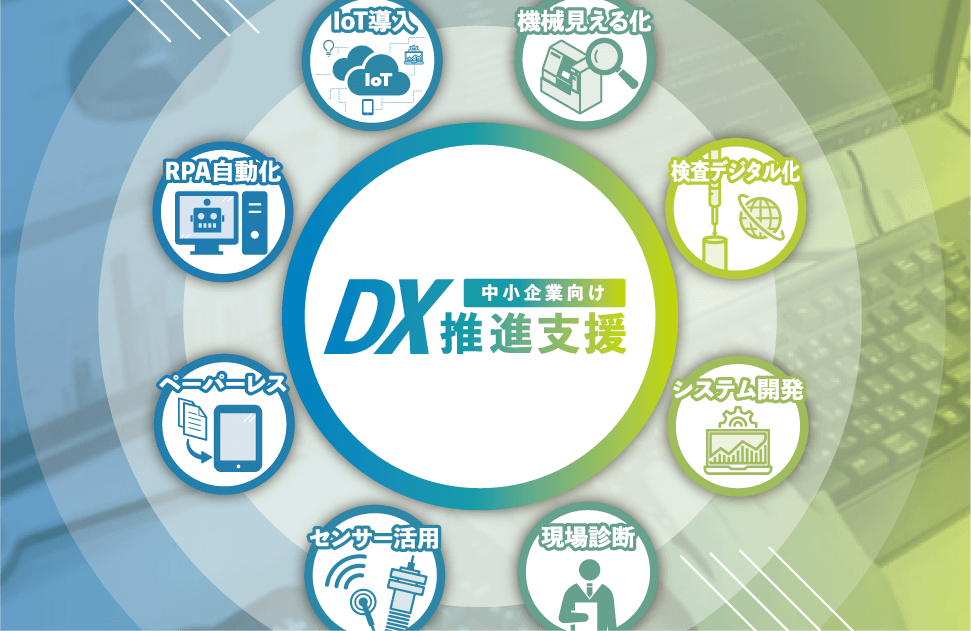

Support for DX promotion

We will support DX promotion by proposing a system that fits the customer, utilizing our systemization and digitalization know-how cultivated with the die and die manufacturing field.

DX promotion support for SMEs

Support for DX promotionWe will support DX promotion by proposing a system that fits the customer, utilizing our systemization and digitalization know-how cultivated with the die and die manufacturing field.

DX Promotion Case Study

You want to promote DX, but "don't know where to start," "don't know if it's applicable to your company," "don't have the personnel to promote DX," etc.

We will help you with our DX promotion case studies.

01

<Do you have any of the following problems? >

・Off-the-shelf software isn't attentive to your needs and doesn't fit the company's business needs.

・There are operations and processes that need to be systematized in a pinpoint manner.

<Our DX Promotion Case Study>

Developed an original management system that encompasses the company's workflow: sales support, cost management, production management, drawing management, and factory support.

We develop and provide "fully customized" systems tailored to the workflow of individual companies.

02

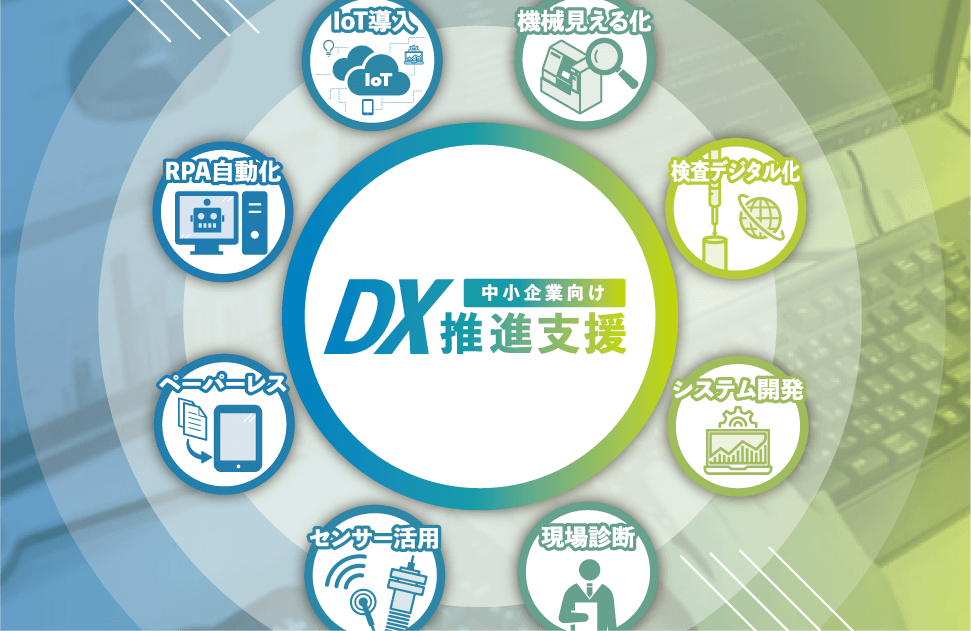

<Do you have any of the following problems?>

・Paper management of drawings and check sheets at the manufacturing site is complicated.

・Printing time and printing costs are high.

<Our DX Promotion Case Study>

Introduced tablets to manufacturing sites, partially eliminating paper-based management.

Transition to electronic data management via tablets

・Reduced printing costs:30,000 yen/month

・Reduced movement:26,400 steps/month

・Reduction of man-hours:39,600 seconds/month

We can help you select which tasks should be paperless, as well as introduce and utilize tablets and large monitors.

03

<Do you have any of the following problems? >

・We don't know what kind of business We can use RPA (Robotic Process Automation) for.

・introduced the system, but has not been able to fully utilize it due to lack of human resources.

<Our DX Promotion Case Study>

Automation of some operations in manufacturing and indirect departments by RPA

[RPA application examples & hours saved/month]

・System registration of machining conditions:33H

・Cost registration of repeat items :42H

・Automatic printing of machining drawings :22H

・Automatic Order Sales Entry :64H

・Automatic emailing of delivery receipts:66H

We will assist you in identifying the tasks to be automated [before introduction] and how to utilize them [after introduction].

04

<Do you have any of the following problems? >

・We want to have stable production.

・To reduce man-hours and costs for production

<Our DX Promotion Case Study>

[Visualization of tool damage and tool life]

Developed a system that uses load sensing technology to feed back the results of tool condition judgment to the machine tool. This has optimized and halved the number of tools used and significantly reduced the total machining time.

[Die set for automatic die positioning]

Developed a device and dedicated evaluation program that automatically adjusts mold positions using load sensing technology.The processing capacity is also improved by controlling the variation of the workpieces and the variation due to the equipment.

Using load sensing technology, we measure and analyze data to help visualize processes and reduce production man-hours.

05

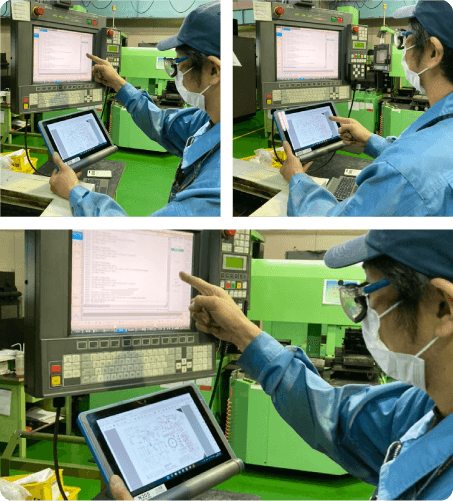

<Do you have any of the following problems? >

・You don't know if a machine is available until you go to see it every time.

Inability to find a way to share a machine with a small number of machines

<Our DX Promotion Case Study>

Created an indicator panel that shows from anywhere in the factory whether someone is using the measuring machine by combining a microcomputer and wireless communication.

・Wasteful round trip Reduced travel:More than 100 steps/month

・Reduced waiting time in front of the measuring machine:10 hours/month

We can help you create an environment where the availability of measurement equipment and other factory equipment can be seen from anywhere in the factory.

06

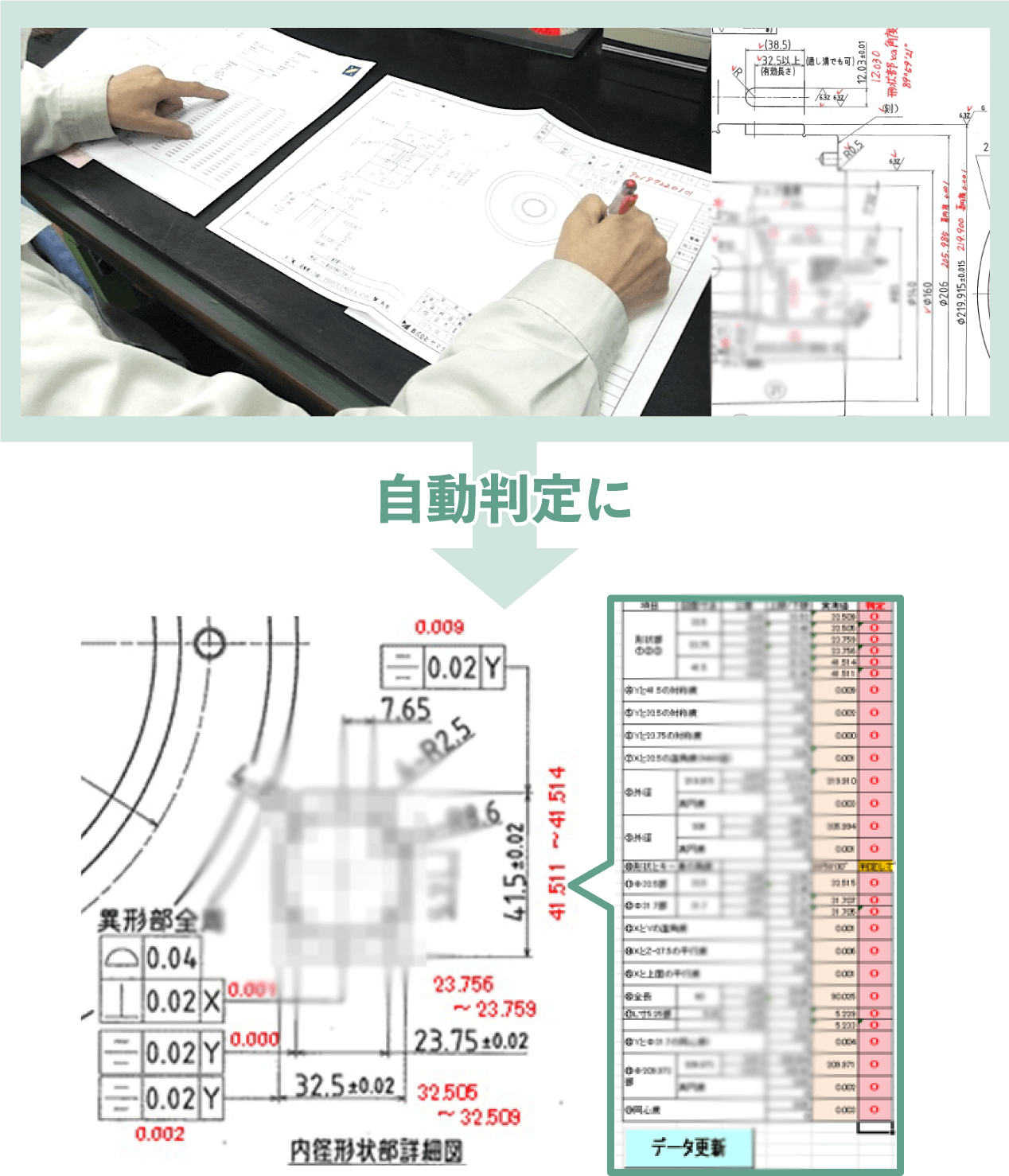

<Do you have any of the following problems? >

Time consuming to fill out and check product inspections

We want to eliminate transcription errors on inspection drawings, etc.

<Our DX Promotion Case Study>

Developed a system that enables "automatic judgment" of conventional "handwritten transcription work. It reduces transcription errors and shortens work time.

・Decrease in the number of returns in the inspection process 80% reduction

・Reduction of work hours by automation Reduction of 50 hours per month

We can help you automate inspection drawings to reduce errors and automate pass-fail.

OTHER SERVICES

Yamanaka Eng is developing various business

Optimize the Production with Total Solution

Contact us if you have any question.