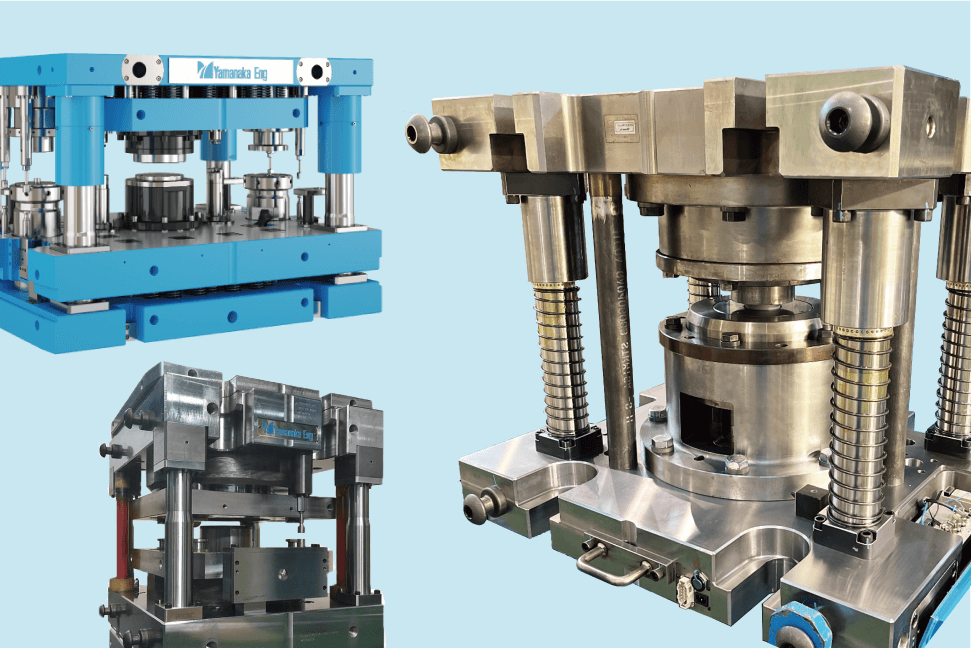

Design and manufacture of all types of die sets

We design and manufacture die sets to meet customer requirements, including smart die sets with monitoring equipment, high-precision die sets and closed die sets.

DIESET

DIESETWe design and manufacture die sets to meet customer requirements, including smart die sets with monitoring equipment, high-precision die sets and closed die sets.

A die set is a jig and tool used to attach a die for plastic forming to a press in order to maintain the correct positional relationship between the upper and lower dies.

It consists of a forming section that contacts the material to form the product, a mounting section that mounts the forming section of the press machine, and a pressure receiving section that relieves the pressure acting on the forming section and transfers it to the press machine itself. Each individual part is designed and manufactured to be as simple as possible.

By manufacturing a standard die set that can be used in common, multiple processes and products can be plasticized by simply replacing one part (e.g., the die of the forming section).

If machining accuracy and assembly accuracy are poor, concentricity between the punch side (upper side) and the die side (lower side) cannot be ensured, which adversely affects the die and the product.

There are various types of die sets, and they are used according to the required rigidity, accuracy, and application. For example, for rigidity, there are steel and aluminum alloy types. For precision, there are many die sets that differ mainly in the way the guide posts and bushings are fitted together.

As for applications, a wide variety of products exist, including those for trimming, and they can be applied to all genres, but price, functionality and quality must be taken into consideration before a decision is made.

This die set contains the wiring for sensors and related equipment that are essential for detecting abnormalities in forging, and is contained within the die set.

For more information on on-board sensors and equipment, Please Click here.

Feature

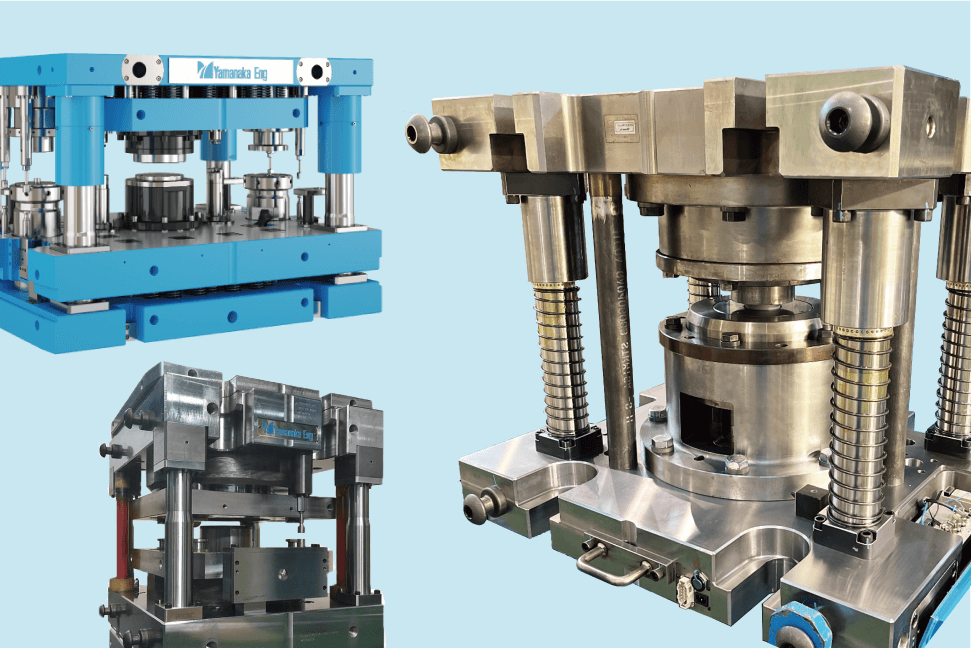

This die set incorporates a mechanism for high-precision forging.

Our unique die set configuration eliminates the influence of the press, resulting in improved concentricity of inner and outer diameters, reduced forgings allowance, and lower material costs.

Technical Information

High-precision die sets are die sets that can achieve dimensional accuracy equal to or better than the cold forging process of the latest high-precision equipment, while utilizing existing press equipment without modification.

The target is die sets and dies in the cold forging process. To significantly reduce dimensional runout of forged products while minimizing the effects of press motion, we apply technologies that eliminate the effects of press motion, high-precision positioning, and zero-clearance forming technologies.

Since these technologies are independent, they can be applied partially as improvements to existing processes.

Feature

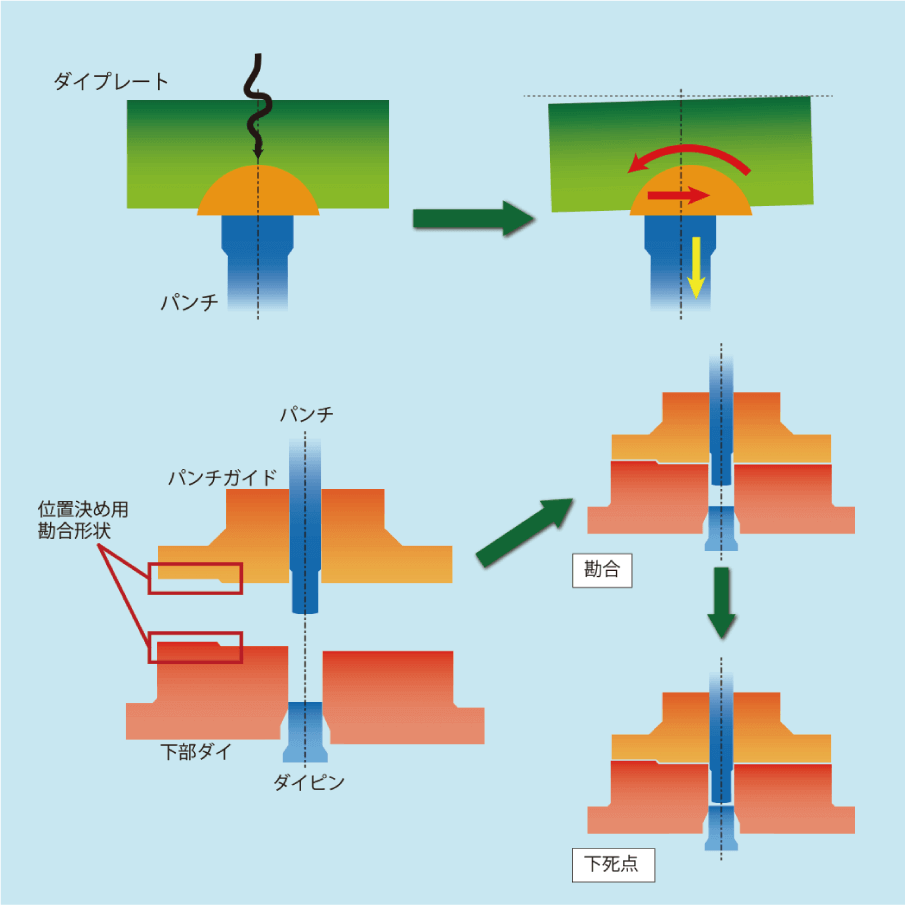

This is Yamanaka Eng's unique spring-loaded closing die set used a special spring.

Technical Information

A closed die set is precisely a "die set for closed forging," a device used to close the upper and lower dies and push the forging material into the space for forming.

Therefore, the die must be closed before forming begins and must withstand the force of the die trying to open under forging pressure. The relationship is closing force ≥ opening force, and that force (closing force) becomes a load on the press and reduces its forging capacity. If the closing force is too large, the force available for forging will be reduced, and if it is too small, the die will open and burrs will occur, and the accuracy of the forged product will not be ensured.

It should be noted that the forming load and the force to open the mold during forging are not constant, but vary. Ideally, the mold should always be closed with approximately 20-40% more force than the force to open it.

Features

Specification

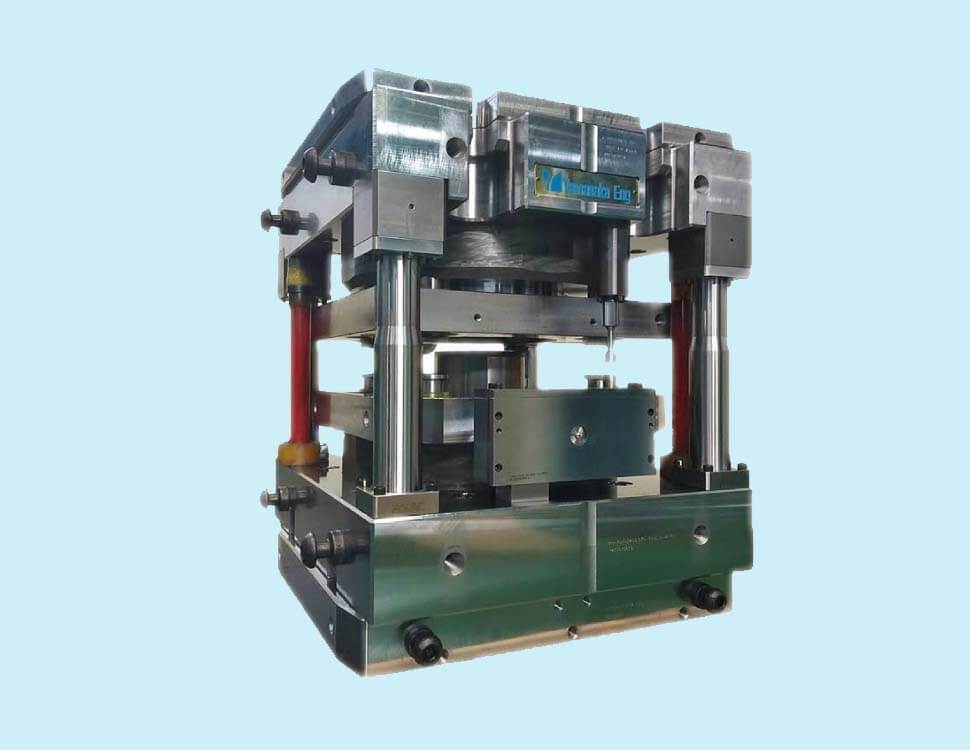

Uniquely designed hydraulic closure die set used a special hydraulic circuit.

Features

Specification

| Parts | Surface pressure distribution | Material properties | Forming load | Blocked load |

|---|---|---|---|---|

| Inner race |

Outer-most diameter ø53 |

SCM420 | 370[tonf] | 40[tonf] |

| Spider |

Torso ø50 / Shaft diameter ø25 |

SCM420 | 390[tonf] | 90[tonf] |

| Bevel gear |

Outer-most diameter ø47.4 |

SCr420H | 360[tonf] | 130[tonf] |

OTHER SERVICES

Yamanaka Eng is developing various business

Optimize the Production with Total Solution

Contact us if you have any question.