Lineup

Tools Manufactured by Yamanaka Eng

With the strength of precision cold forging dies, we also produce forging tools for warm/hot/cold combined processes, non-ferrous metal forming, flow forming, and other processes using various forming methods.

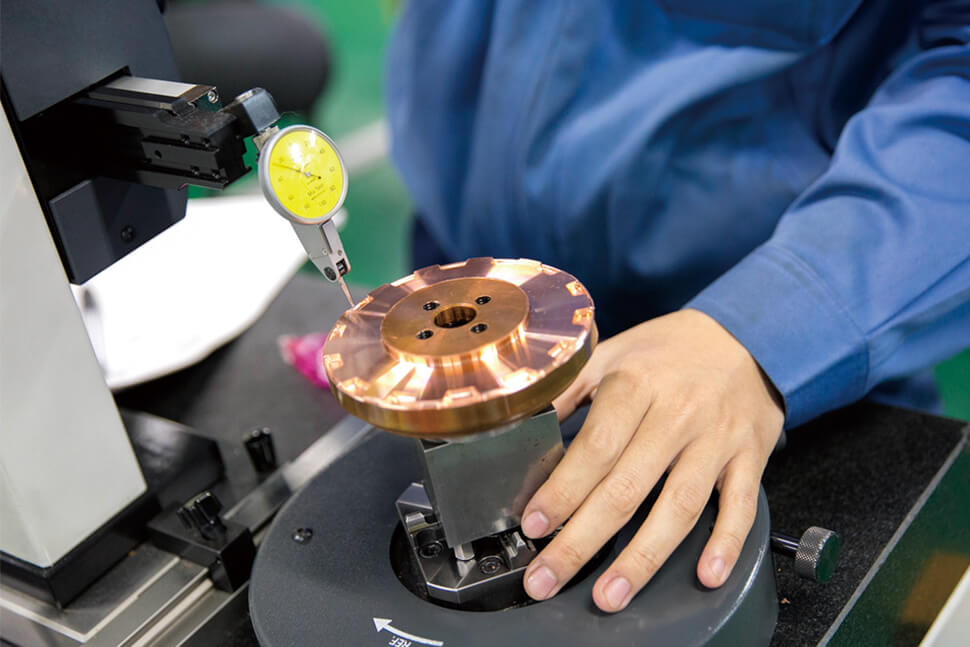

Cold-forging

- High accuracy

- High performance

- High additional value

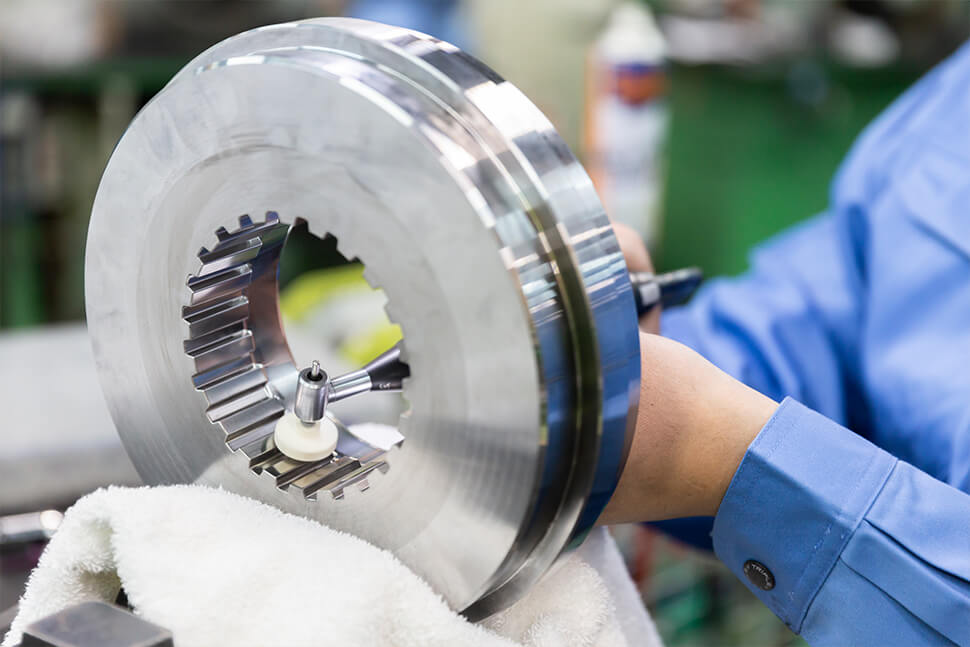

Warm/Hot/Cold Combined Forging

Near net-shape manufacturing of large forging products with complex geometry.

Non-ferrous Mmetal Forging

A lightweight and energy-saving non-ferrous metal products with complex shape can be produced.

Flow-forming

Incremenral forming process based on rotational movement to manufacture the complex sheet metal products.