Release Date:2024/10/17

What is Chipping? – Causes & Solution with Yamanaka Eng’s Load Sensor

What is Chipping?

Chipping refers to the phenomenon of wear caused by tiny fractures on the surface of a die or small breakages at the tool’s cutting edge. Continuing to use dies or tools in a chipped state without replacement can lead to further chipping, resulting in reduced machining accuracy and potentially causing damage to the dies or tools.

Therefore, it is crucial to implement early prevention measures and immediately pause operations to replace dies or tools as soon as chipping is detected.

Causes of Chipping and Measures

Here are the causes and solutions for chipping.

Causes and Measures for Die

- Reducing initial crack occurrence

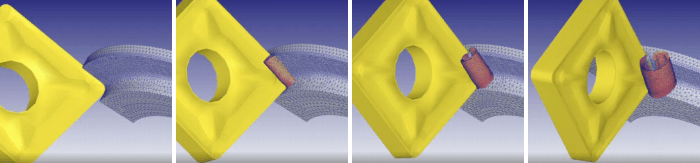

Chipping refers to low-cycle fatigue failure of a die or tool caused by repeated manufacturing operations. It occurs when multiple cracks form in different locations and propagate until they connect. To enhance fatigue strength, it is necessary to improve heat treatment conditions, increase hardness by changing materials, and design dies to minimize stress concentration.

Causes and Measures for Cutting Tools

- Reconsideration of tool materials and modification of the cutting edge shape

Tools made from cemented carbide or ceramics possess high hardness but are prone to impacts and vibrations due to their brittleness. Because of these characteristics, chipping is more likely to occur when the hardness of the tool significantly exceeds that of the workpiece.

As a countermeasure, using tools with greater toughness is recommended. Additionally, rounding the corners of the cutting edge (adding a corner radius) can be effective, as sharp edges are more susceptible to chipping.

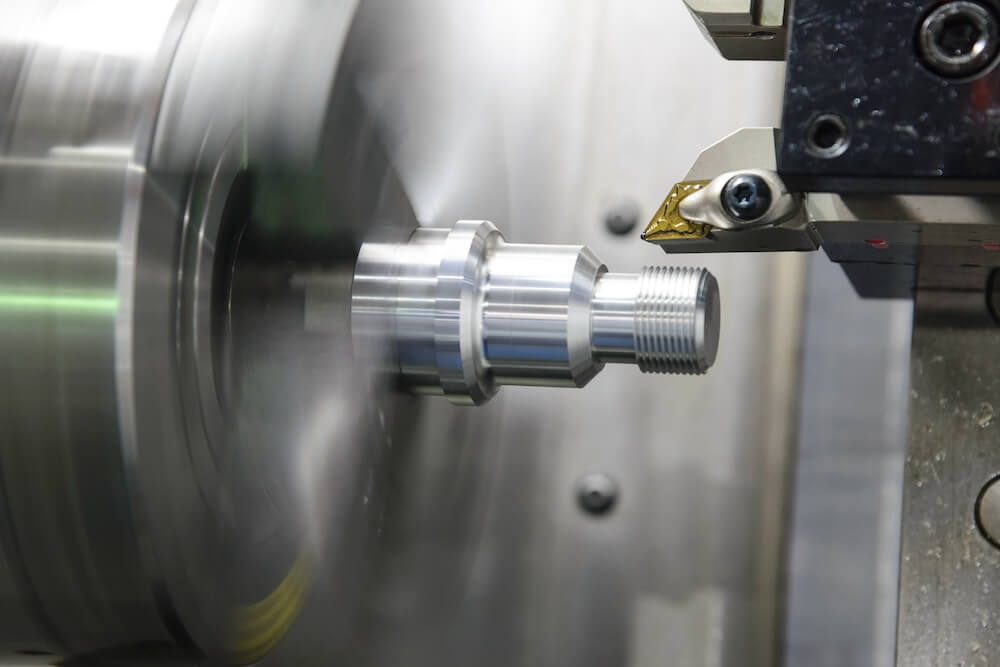

- Improving cutting/machining conditions

Under conditions such as high cutting speeds, large feed rates, and rapid changes in cutting temperature, frictional heat and cutting resistance tend to increase, making chipping more likely to occur. Effective countermeasures include gradually reducing the cutting speed and feed rate while monitoring performance, and improving the application and volume of coolant to enhance lubrication.

How to Prevent Chipping Thoroughly

With the measures introduced above, it is possible to reduce the occurrence rate of chipping. However, it is impossible to eliminate chipping, as the durability of dies and tools inevitably decreases over time with continued use.

For dies, hardening can help reduce the risk of chipping, but it comes with the drawback of increasing the likelihood of cracks forming.

For tools, risks such as chipping can be avoided by setting limits on operation hours or usage cycles and replacing tools before these limits are exceeded. However, regular replacement is inefficient in terms of cost, as tools are replaced before reaching their full lifespan. Additionally, it does not address sudden tool damage, which can lead to machining defects.

In an ideal production environment, dies should be replaced before they begin to affect product quality. For tools, they should be used up to their actual lifespan rather than being replaced based on estimated lifespans.

In the following section, we will introduce a case study focusing on chip detection in dies. By using a piezoelectric load sensor, even small instances of chipping were detected, allowing the equipment to stop automatically and preventing the production of defective products.

If you are struggling with chipping issues, we encourage you to read on for more details.

Case Study: Stopping Equipment to Prevent Defective Products Due to Chipping

In this case study, the customer faced challenges in the machining process for automotive components:

- Defective products were occasionally produced due to chipping on the dies or tools.

- Their existing sensors were unable to detect small instances of chipping.

Solution

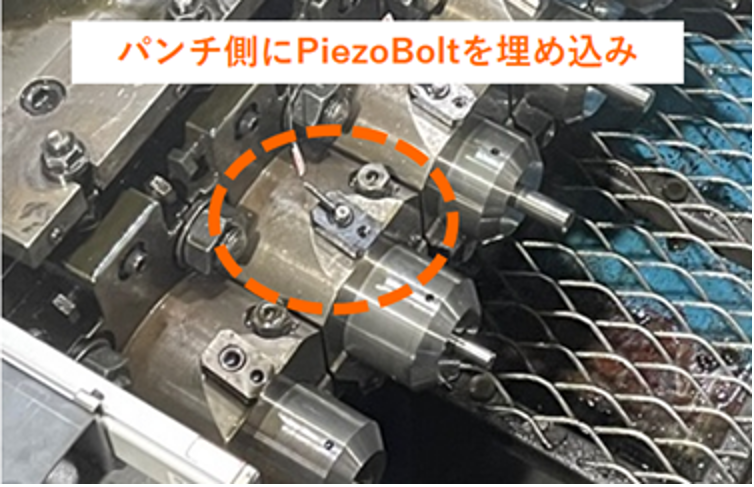

As for a solution, we mounted the piezoelectric sensor, PiezoBolt, on the punch to measure load.

※What is the Bolt Piezoelectric Load Sensor “PiezoBolt”?

“PiezoBolt” is the load sensor with an embedded sensor unit using a piezoelectric element inside the bolt. It is capable of measuring minute load changes by leveraging the piezoelectric effect, which generates voltage when force (pressure) is applied.

For more detailed information, please click the link below.

Result

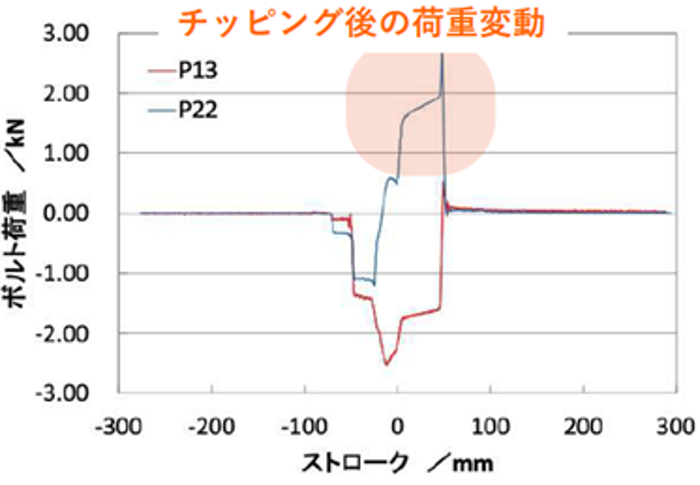

As a result, we discovered that the occurrence of chipping causes the load fluctuation. Even tiny chips caused magnificent changes in pressure status.

We learned from the result that we can reduce the frequency of quality control by building a system, that pauses the equipment during the manufacturing process.

Conclusion

Hope you enjoyed this article.

There are some ways to prevent chipping, and this time we introduced a solution with our load sensor. If you are considering introducing this solution in a production site or have trouble with wear, cracking, and galling, please contact us.