Release Date:2024/09/03

What is Slug-Pulling? – Causes, How to Prevent Slug-Pulling & Case Study

What is Slug-Pulling

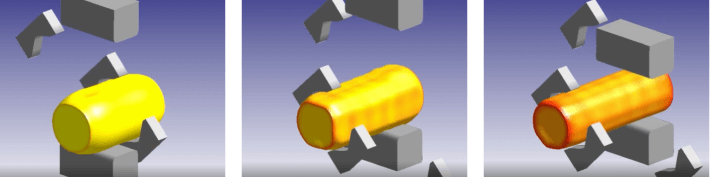

Slug pulling refers to the phenomenon where slugs remain on the surface of the die instead of falling off during progressive stamping or punching processes. If production continues with slugs on the die surface, it can cause dents in the material, leading to defective. Products or potential damage to the die.

Therefore, early detection of slug pulling is crucial to prevent significant impacts on the overall production process.

Causes of Slug-Pulling

The following are the primary reasons for slug pulling:

- A vacuum state occurs between the clearance of the drawing punch and the slug.

- Forming oil film adheres to the die.

- Residual magnetism remains on the punch.

- Burrs can cause crimping at the edges of the punches and dies.

How to Prevent Slug-Pulling

The following methods are effective in preventing slug pulling:

- Reviewing Tool Geometry: Regularly assess and adjust the shape of the tools.

- Optimizing Forming Oil Application: Ensure the correct amount of forming oil is applied.

- Demagnetizing Punch Tooling: Remove any residual magnetism from the punch.

- Complex Shape Design: Implement more complex designs for the drawing.

- Adding Pneumatic Circuits: Incorporate pneumatic circuits in the punch to prevent slugs from sticking.

- Using a Slug Pulling Sensor: Employ sensors specifically designed to detect slug pulling.

Recently, the use of sensors has become increasingly prominent in production sites. However, there are concerns that when products are small, the sensors may fail to detect slug pulling, resulting in the production of many defective items.

In this article, we will introduce a case study that demonstrates how to prevent defective products caused by slug pulling, regardless of the size or thickness of the items.

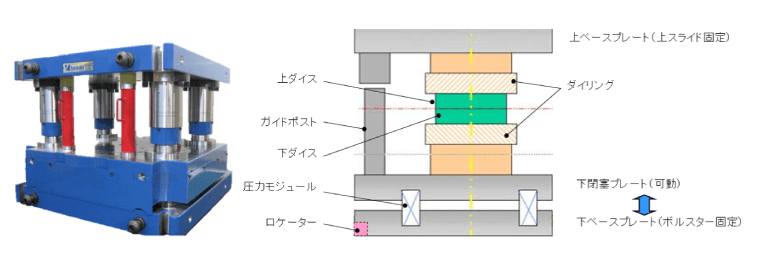

Case Study: Detection of Slug-Pulling in Blanking of a Motor Core

In this case study, the customer encountered challenges during the blanking process of a motor core due to slug pulling:

- Inability to detect slug pulling with the sensors they had already installed.

- High costs associated with the sensors they had already installed.

Solution

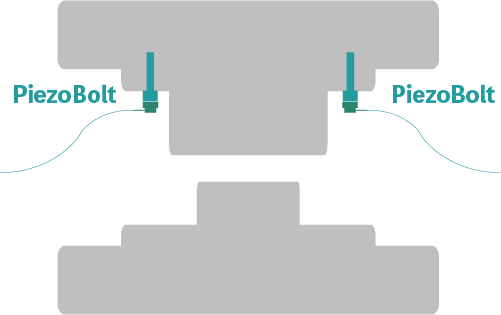

As a solution, we installed two piezoelectric load sensors, named “PiezoBolt”, behind the punch tooling and conducted measurements.

※What is the Bolt Piezoelectric Load Sensor “PiezoBolt”?

PiezoBolt is the load sensor with an embedded sensor unit using a piezoelectric element inside the bolt. It is capable of measuring minute load changes by leveraging the piezoelectric effect, which generates voltage when force (pressure) is applied.

For more detailed information, please click the link below.

Result

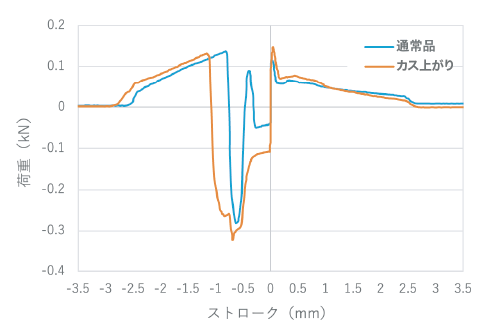

As a result, we discovered significant discrepancies in the load trends on the PiezoBolts between normal conditions and those with slug pulling occurrences.

By thresholding the forming load data, we established a system that transmits alerts and pause signals when abnormal data is detected. This allows us to prevent defective products from being released.

Conclusion

We hope you enjoyed this article.

There are some ways to prevent slug pulling, and this time we have demonstrated a solution with our sensor.

If you are considering introducing this solution in a production site or have trouble with wear and cracking, please contact us.