By utilizing CAE (Computer-Aided Engineering) in crimping processes, you can predict the deformation behaviors of multiple materials and clamping force after the process, thereby preventing potential defects.

This article will focus on Crimping, discuss the benefits of CAE analysis, and share case studies.

Contents

What is Crimping?

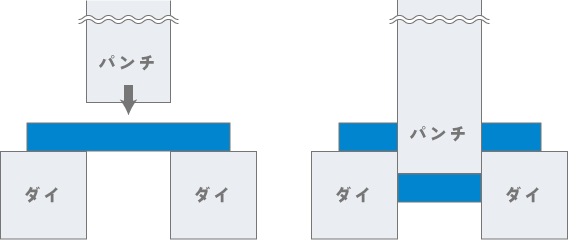

Crimping is a method of joining two sheet-shaped parts by utilizing plastic deformation.

There are two types of methods:

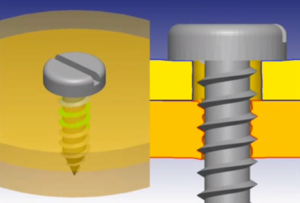

- Riveting: This method involves inserting a rivet into pre-drilled holes in two sheet materials and deforming the rivet by pressing to fasten the parts together.

- Interlocking and Bending: This method combines materials with interlocking shapes and bends them together using pressing to create a tight bond between the two components.

Advantages:

- Enables fast processing.

- Easy to automate.

- Produces stable strength.

- Particularly suitable for assembling precision sheet metal components.

Disadvantages:

- Riveting requires additional components (e.g., rivets), which increases costs and processing time.

- Once crimped, the components are difficult to disassemble.

Common Types of Crimping

- Seaming

- Hemming

- Corner Crimping/Clinching

- Riveting

Benefits of CAE analysis for Crimping

CAE analysis for crimping enables you to predict the deformation behaviors of multiple materials and the clamping force after crimping. By setting the proper material thickness, clearance, and crimp shape, you can prevent potential defects in subsequent processes and reduce component production costs.

Examples of Crimping Simulations with CAE Solution

Now, we will introduce you examples of simulations using the CAE software DEFORM.

※What is the CAE software “DEFORM”?

DEFORM is the comprehensive machining simulation software for all types of metal processes, including forging, cutting, and heat treatment.

With a wide variety of analysis functions, our customers come from various fields, including the automotive, steel, aerospace, electrical/electronics, and chemical industries.

For more detailed information, please click the link below.

The CAE software “DEFORM” is your best partner in plastic forming

Case Studies (Click on the image to visit the 3D animation page)

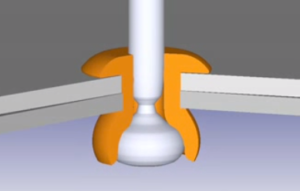

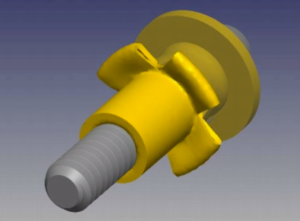

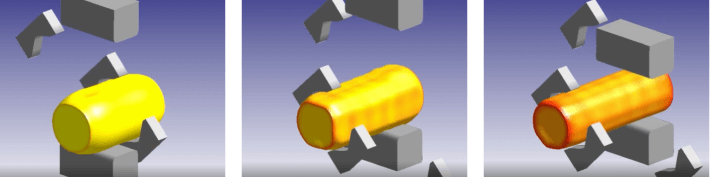

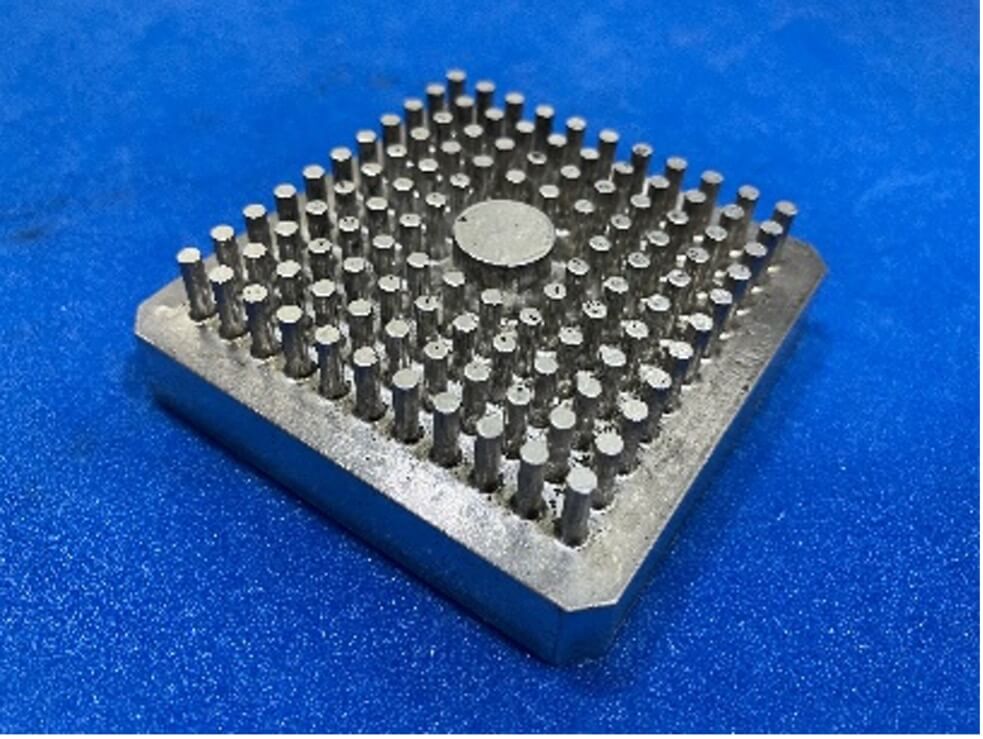

Here are case studies of crimping processes, such as bolt crimping and riveting, using multiple deformable tools.

The deformation behaviors of each material during the crimping process can be observed, and forming conditions such as anvil action timing, velocity, and temperature result in variations in the final shapes.

Conclusion

Thank you for reading.

By utilizing CAE, it is possible to prevent defects in advance, while also reducing costs and shortening lead times. The CAE software DEFORM offers a wide range of features to support designers, including capabilities for additional processes, data analysis, experimental design modules, and optimization modules.

If you have any questions or concerns about product design or manufacturing, please feel free to contact us.