Release Date:2024/09/03

What is Heat Treatment Simulation with CAE? – Benefits & Case Studies

By utilizing CAE (Computer-Aided Engineering) in heat treatment processes, you can predict deformation, microstructural changes, quench cracks, and hardness throughout the process. This allows you to prevent potential defects and optimize the heat treatment process.

In this article, we will introduce Heat Treatment, discuss the benefits of CAE analysis, and share case studies.

Contents

What is Heat Treatment?

Heat Treatment is a process of modifying and improving the properties of metals by heating them above a certain temperature and then cooling them using appropriate methods.

Advantages:

- Enhances the functionality and strength of products based on their intended applications.

- Improves machinability and grindability during manufacturing.

Disadvantages:

- Requires destructive testing to verify the internal quality of products.

- Demands strict control of processing conditions to ensure consistent results.

Types of Heat Treatment:

Heat treatment can be broadly divided into two categories:

Modification:

- Induction Hardening

- Electron Beam Hardening

- Laser Quenching

- Carburizing

- Nitriding

Improvement:

- Normalizing

- Annealing

- Quenching

- Tempering

Benefits of CAE Analysis for Heat Treatment

CAE analysis for heat treatment provides valuable insights into the process by enabling precise predictions of deformation, microstructural changes, quench cracks, and hardness. These capabilities allow manufacturers to optimize heating and hardness. Additionally, this approach contributes to reducing production costs by improving efficiency and avoiding unnecessary trial-and-error methods.

Examples of Heat Treatment Simulation with CAE Solution

Now, we will introduce you to examples of simulations using the CAE software DEFORM.

※What is the CAE software “DEFORM”?

DEFORM is a comprehensive machining simulation software for all types of metal processes, including forging, cutting, and heat treatment.

With a wide variety of analysis functions, our customers come from all fields, including the automotive, steel, aerospace, electrical/electronics, and chemical industries.

For more detailed information, please click the link below.

The CAE software DEFORM is your best partner in plastic forming

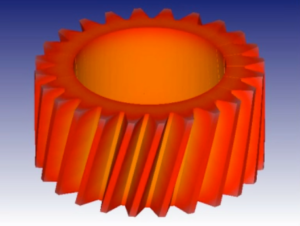

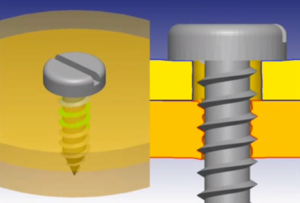

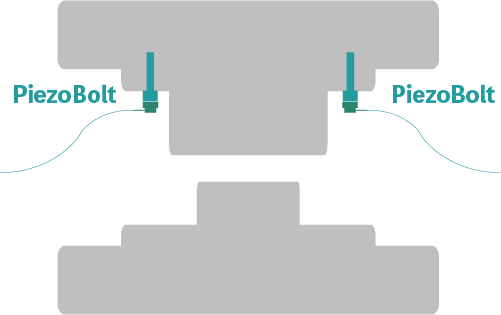

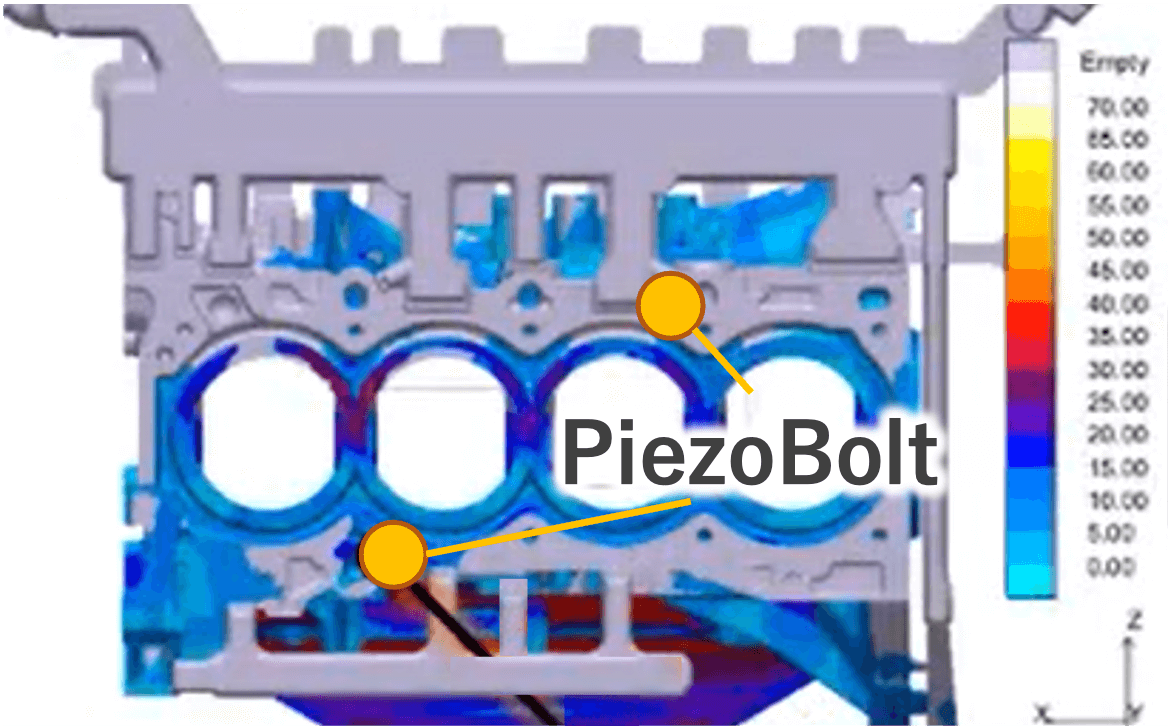

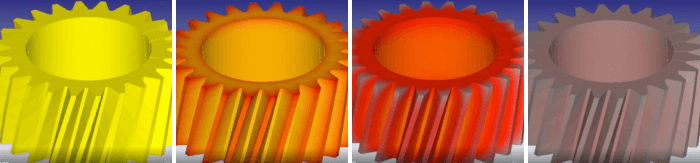

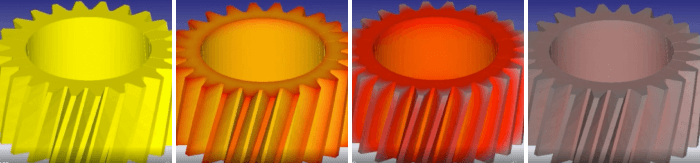

Case Studies (Click on the image to visit the 3D animation page)

These are case studies of simulations that predict temperature changes and dimensional changes during heat treatments, such as induction heating, furnace heating, quenching, and carburizing.

The deformation and microstructure after the heat treatment vary depending on cooling conditions and the placement of the products during the process.

Conclusion

Thank you for reading. We hope you found this article helpful.

By utilizing CAE, it is possible to prevent defects in advance, while also reducing costs and shortening lead times. The CAE software DEFORM offers a wide range of features to support designers, including capabilities for additional processes, data analysis, experimental design modules, and optimization modules.

If you have any questions or concerns regarding product design or manufacturing, please feel free to contact us.