By utilizing CAE (Computer Aided Engineering) in shearing processes, you can predict rollovers, burrs, and work hardening around the cut edge, thereby preventing potential defects.

In this article, we will focus on Shearing and introduce its overview, the benefits of CAE analysis, and case studies.

Contents

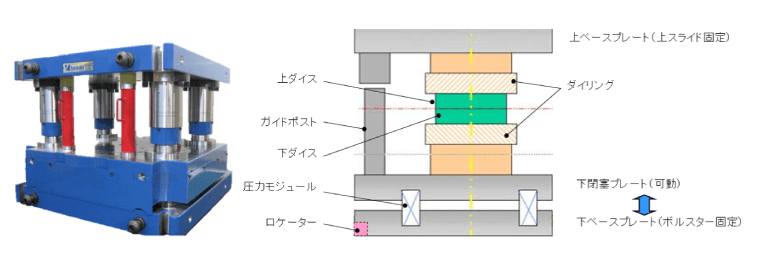

What is Shearing?

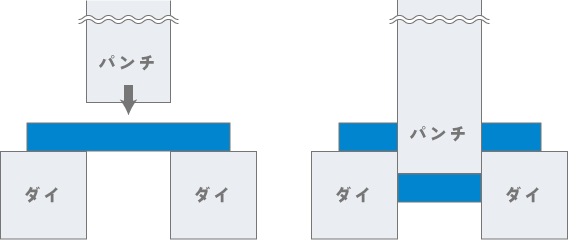

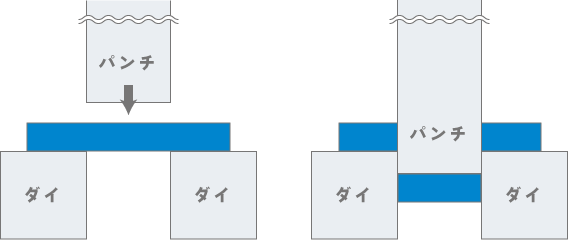

Shearing is a metal forming process that cuts materials into desired shapes and dimensions using a set of punches and dies with cutting blades at their interface.

Advantages:

- Shearing offers high productivity compared to other cutting methods, such as sawing, grinding, machining, or laser cutting.

Disadvantages:

- If the punch and die clearance is incorrectly set or production is poorly controlled, defects such as cracks and burrs can easily occur on the material.

Benefits of CAE Analysis for Shearing

CAE analysis for shearing processes enables you to predict rollovers, burrs, and work hardening around the cut edge that occur during the process. This allows for the design of appropriate tool shapes and forming processes, helping to prevent potential defects in subsequent processes and reduce production costs.

Examples of Searing with CAE Solution

Here are some examples of analyses using the CAE software “DEFORM“.

※What is the CAE software “DEFORM”?

DEFORM is a comprehensive machining simulation software for all types of metal processes, including forging, cutting, and shearing.

With a wide variety of analysis functions, our customers come from all fields, including the automotive, steel, aerospace, electrical/electronics, and chemical industries.

For more detailed information, please click the link below.

The CAE software “DEFORM” is your best partner in plastic forming

CASE STUDIES (Click on the image to visit the 3D animation page)

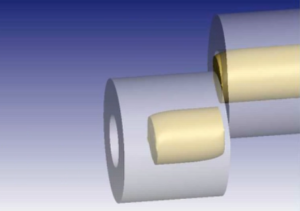

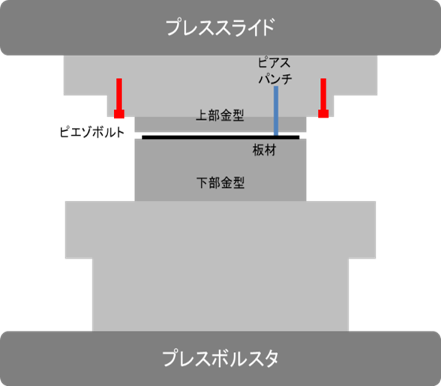

Here are case studies of simulations for wire rod cutting, trimming (a post-forming process for pressing and forging), and other shearing processes using DEFORM.

The differences in punch and die clearances, material properties, and shearing times result in variations in rollovers and burrs around the cut edge.

Conclusion

We hope you found this article helpful.

By utilizing CAE, it is possible to prevent defects in advance, while also reducing costs and shortening lead times. The CAE software DEFORM offers a wide range of features to support designers, including capabilities for additional processes, data analysis, experimental design modules, and optimization modules.

If you have any questions or concerns regarding product design or manufacturing, please feel free to contact us.