Release Date:2024/09/03

What is Free/Open Forging Simulation with CAE? – Benefits & Case Studies

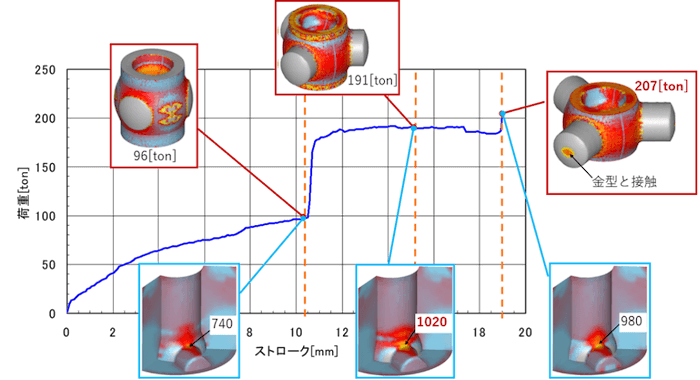

By leveraging CAE (Computer-Aided Engineering) in free/open forging, it becomes possible to visualize the progression of load, deformation, and temperature changes during the metal forming process. Additionally, CAE can predict potential defects, such as cracks, that may occur during forming.

In this article, we will provide an overview of free/open forging, discuss the benefits of CAE analysis, and share case studies to illustrate its practical applications.

Contents

What is Free/Open Forging?

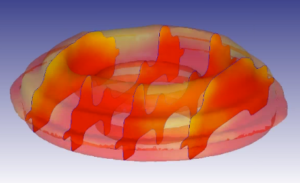

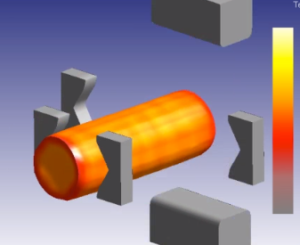

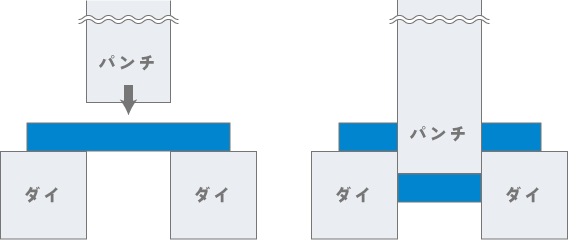

Free forging is a forming method that uses simple tools with smooth or curved surfaces. The material is pressed and in a free (open) state. During the process, the material or tools are moved and rotated, allowing the same part of the material to be pressed multiple times. With each press, the tools advance, and the material gradually takes on the desired shape by the end of the process.

This method is primarily used for rough forming of large components. The advantages of free forging include lower forming forces per operation and the ability to handle large materials with relatively inexpensive equipment. However, since the resulting material is in a rough state, additional processes such as pressing or machining are required to produce the final product.

Common types of free forging include cogging, upsetting, and radial forging.

Benefits of CAE Analysis for Free/Open Forging

CAE (Computer-Aided Engineering) analysis for free forging provides several advantages. It allows you to visualize the progression of load, deformation, and temperature changes in the material during the forming process. Additionally, it enables the prediction of potential defects, such as cracks, that may occur during forming.

By optimizing and setting appropriate anvil operations based on the analysis, defects can be prevented in advance, ensuring smoother production. This proactive approach helps reduce component production costs significantly.

Examples of Free/Open Forging Simulation with a CAE Solution

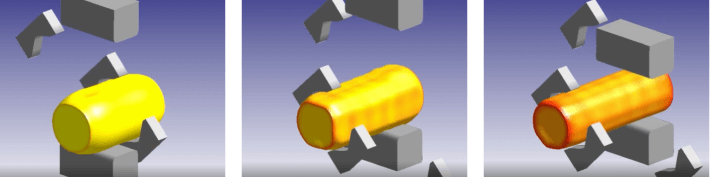

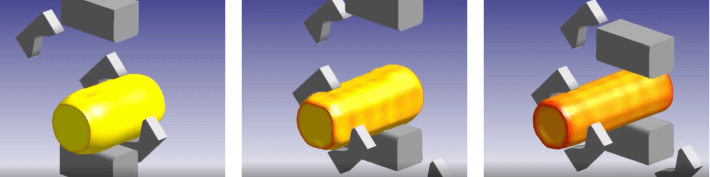

Now we would like to introduce case studies of simulations conducted using the CAE software “DEFORM”.

※What is “DEFORM”?

DEFORM is the comprehensive simulation software for all types of metal processes, including forging, machining, and heat treatment.

With a wide variety of analysis functions, our customers come from various fields, including the automotive, steel, aerospace, electrical/electronics, and chemical industries.

For more detailed information, please click the link below.

The CAE software “DEFORM” is your best partner in plastic forming

Other Case Studies (Click on the images to visit the 3D animation pages)

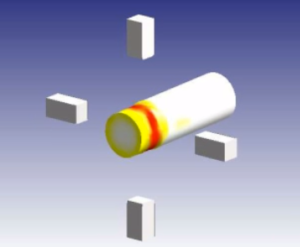

These examples include various free forging processes, such as cogging and 4-die GFM (General Forging Machine) forging.

The following geometry can vary significantly depending on forming conditions, including the timing and speed of multiple anvil operations, as well as temperature.

Thank You for Reading

We hope you found this article informative and helpful.

By leveraging CAE, it is possible to prevent defects in advance, while also reducing costs and lead times. The CAE software “DEFORM” offers a wide range of features to support processes, data analysis, experimental design modules, and optimization modules.

If you have any questions or concerns regarding product design or manufacturing, please feel free to contact us.