Release Date:2024/09/03

How to Reduce Seizure of Metals – What are Seizures? & How to Evaluate Seizure with CAE Analysis

Contents

What are Seizures?

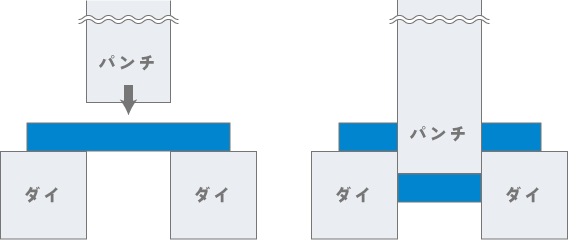

Seizures are a phenomenon in which friction between a tool and a workpiece raises the temperature, causing the workpiece material to weld to the tool. This phenomenon is commonly observed in products subjected to significant friction, such as cutting tools and press dies.

Causes of Seizures

The main causes of seizures are as follows:

- Inadequate type or amount of lubricant: The lubricant used is either unsuitable or insufficient.

- Insufficient lubrication: Machining conditions exceed the performance of the lubricant, leading to inadequate lubrication.

- High friction surface temperature: The friction surface between the tool and the workpiece becomes extremely hot, causing the metal to melt.

- High surface roughness: The surface roughness of the tool and the workpiece is too high, increasing the likelihood of seizure.

How to Prevent Seizures

To prevent seizure, the following measures should be taken:

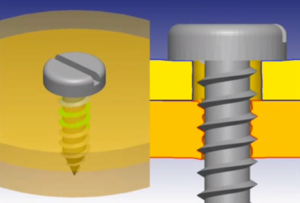

- Use adequate lubrication: Apply the appropriate type and amount of lubricant between the tool and the workpiece.

- Improve tool surface quality: Increase the surface smoothness of the tool or apply surface modifications such as coatings.

- Select appropriate tool materials: Use tool materials that are less prone to adhere to the workpiece material.

Case Study: CAE Analysis to Evaluate Seizure Degree

Now, we will focus on automotive gear products and introduce a case study aimed at reducing seizure occurrences.

Seizure is generally evaluated by combining surface pressure and velocity using CAE software.

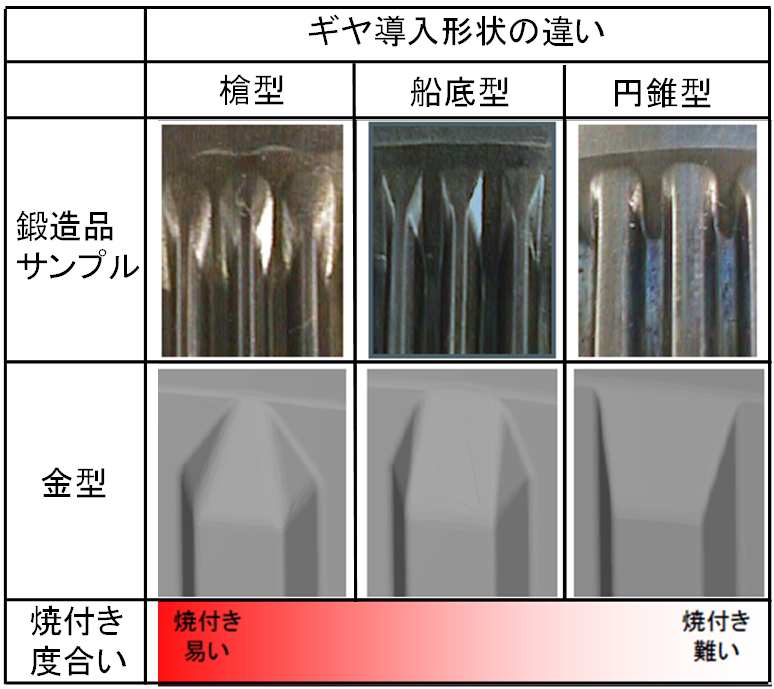

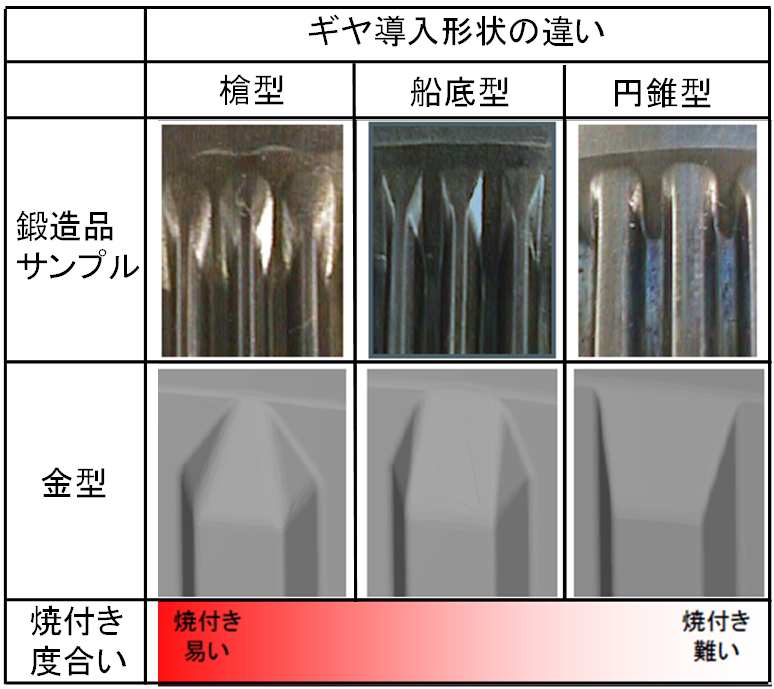

However, in gear forming processes like this case, while it was known that differences in gear introduction shapes affect seizure, evaluation was not possible because surface pressure and velocity showed similar distributions.

It is observed that gears with a spear-like introduction shapes are more prone to seize, while those with conical shapes are less prone. The seizure severity for keel/hull-like shaped gear is considered to fall between two.

Evaluation Factors in CAE Analysis

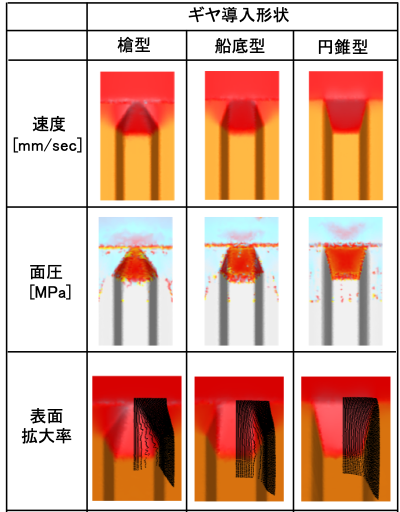

To address this, in addition to the conventional evaluation factors of surface pressure and velocity, we introduced the Surface Expansion Ratio as a new evaluation factor in CAE analysis. This factor accounts for material surface expansion, which varies significantly depending on gear introduction shapes.

By incorporating the Surface Expansion Ratio into the analysis, we evaluated the degree of seizure caused by differences in gear introduction shapes.

Results:

Although surface pressure and velocity showed no significant differences across gear introduction shapes, the Surface Expansion Ratio revealed clear variations in material surface expansion. This allowed us to reliably evaluate seizure severity based on gear introduction shapes.

As a result, we confirmed that the Surface Expansion Ratio is a valuable factor for evaluating seizure on CAE analysis.

Conclusion

We hope you found this article informative.

As demonstrated, utilizing CAE analysis allows you to determine the degree of seizure occurrence during the design stage and select appropriate gear introduction shapes. This improves design quality and helps prevent seizure issues.

While this article focused on gear product seizures, we also offer verification services for other products and other types of damage. If you encounter any challenges in your production processes, please feel free to contact us.