Release Date:2024/09/03

Case Studies of Defects/Failures in Pressing – How to Prevent Punch Breakages & Contamination

Do you face challenges like these?

- “Detecting defects and other issues quickly is not easy. Visual inspection of punch breakages during pressing processes on-site is particularly challenging.”

- “We experienced producing large amounts of defective products because we failed to notice scraps like burrs and slugs stuck in the dies in advance.”

In this article, we will introduce two case studies where Bolt Piezoelectric Load Sensors were used to detect defects and issues during pressing processes.

Contents

What is Press Working?

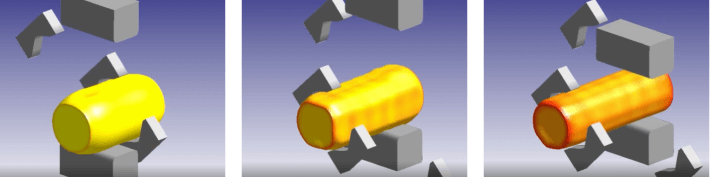

Press Working is a metal forming method in which the metal material is placed between dies and pressurized by a press machine to deform it into the desired shape.

Examples of products produced by the press working include:

- Bodies and doors for automobiles.

- Exterior components for home appliances.

- Substrates and cases for electronic devices.

Press Working Methods

Common press working methods are as follows:

- Shearing

- Bending

- Drawing

- Press-Forming

- Press-Forging

Common Defects in Press Working

Pressing is the most common method in “plastic forming” and is highly suitable for mass production due to its ability to process materials quickly and continuously.

However, many may have faced challenges caused by the following defects and failures:

- Rollover

- Burr

- Spring Back

- Crack

- Wrinkle

- Galling

- Slug Pulling

- Bow/Distortion/Twisting

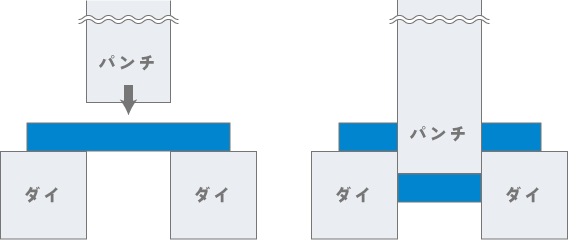

Today, we will introduce case studies of defects detected in “Drilling (Piercing),” which is classified under the shearing process, as well as defects in the drawing process.

Case Study 1: Detection of Tool Defects/ Failures (Punching/Piercing Process)

Solution with Yamanaka Eng’s Bolt Load Sensor

The first case study focuses on detecting punch failures and breakages that occur during punching processes in press working.

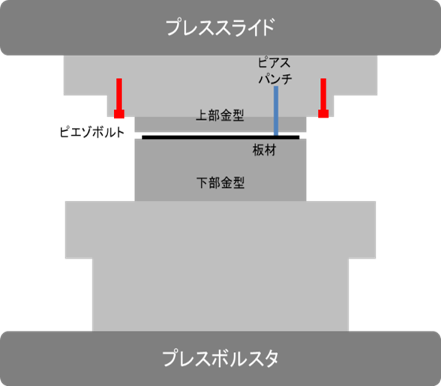

Punch failures frequently occur in processes where multiple holes are simultaneously produced in sheet metals. As a solution, we mounted two piezoelectric load sensors known as “PiezoBolts” to the die.

※What is the Bolt Piezoelectric Load Sensor “PiezoBolt”?

PiezoBolt is the load sensor with an embedded sensor unit using a piezoelectric element inside the bolt. It is capable of measuring minute load changes by leveraging the piezoelectric effect, which generates voltage when force (pressure) is applied.

For more detailed information, please click the link below.

Monitoring Report

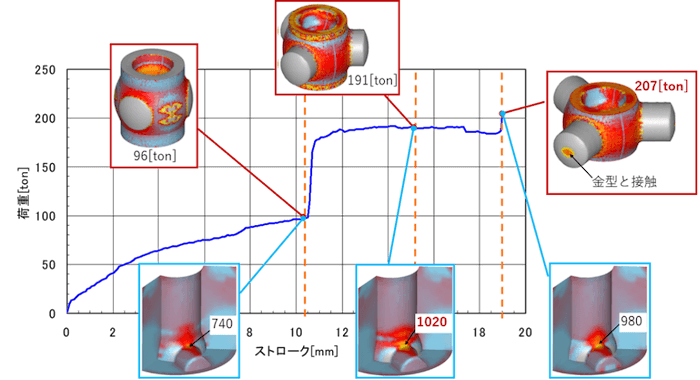

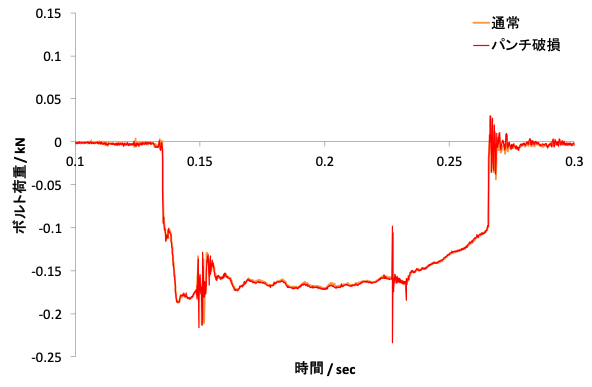

The analysis of the measured signals revealed that the signal obtained during punch breakage differed significantly from the normal signal, as illustrated in the figure below. Additionally, a distinct peak that appeared to represent the impact load at the moment of breakage was successfully captured.

By repeatedly gathering and analyzing the data using this method, clients were able to visualize punch defects and failures effectively. Furthermore, by defining threshold values and setting alerts for abnormal situations, it became possible to:

- Reduce the production of defective products.

- Mitigate damage to dies, machinery, and equipment.

Case Study 2: Defect Detection Caused by Scraps

The second case study focuses on detecting defects caused by scraps, such as burrs and slugs. In this forming process, the issue was that scraps went unnoticed, leading to defective products being mixed in with good products without detection. Because they did not notice scraps, some defective products were produced among good products without being detected.

Solution with Yamanaka Eng’s Bolt Load Sensor

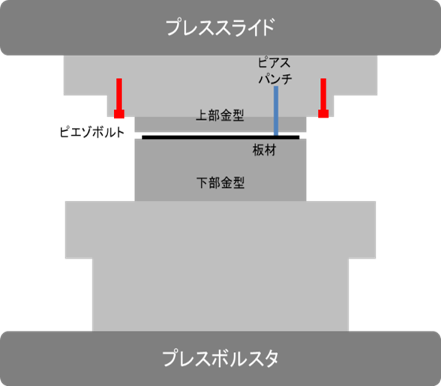

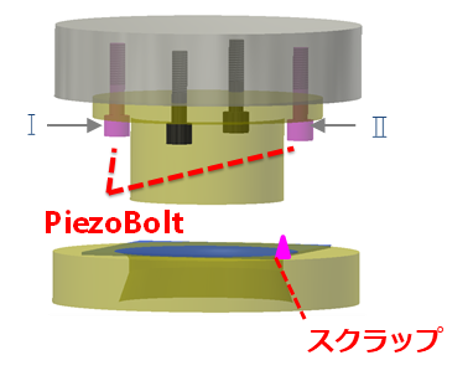

Two Bolt Load Sensors (PiezoBolts) were installed on the left and right sides (I and II) of the upper part of the die set in the plate forming press to monitor the forming load.

Monitoring Report

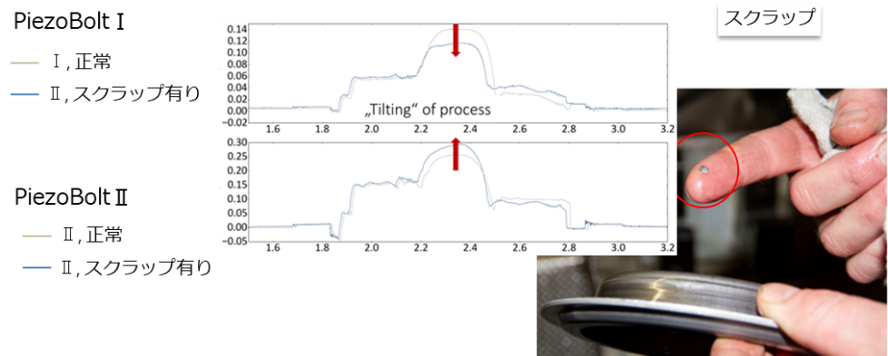

The PiezoBolt is an extremely sensitive sensor that can evaluate even the slightest differences in load when scraps are caught in the dies.

In this case, the system successfully monitored to alert to eccentric load on the dies. Based on the monitoring results, the system was configured to alert operators when the load balances changed.

This setup enabled immediate action in the event of defects in the clients to take immediate action in case of defects or failures, and they could increase production efficiency.

Conclusion

Thank you for taking the time to read this article.

By monitoring with Bolt Load Sensors, it is possible to visualize abnormalities that cannot be detected by human skills alone, such as visual inspection or sound checks. In this article, we focused on press working and introduced some examples, but PiezoBolt can be applied to a wide range of challenges in production sites, including cutting and casting.

If you have any questions or concerns, please feel free to contact us.