Realize High-precision Forgings

with Conventional Presses!

Yamanaka Eng provide well-designed die set for the conventional press that achives high-precision forging.

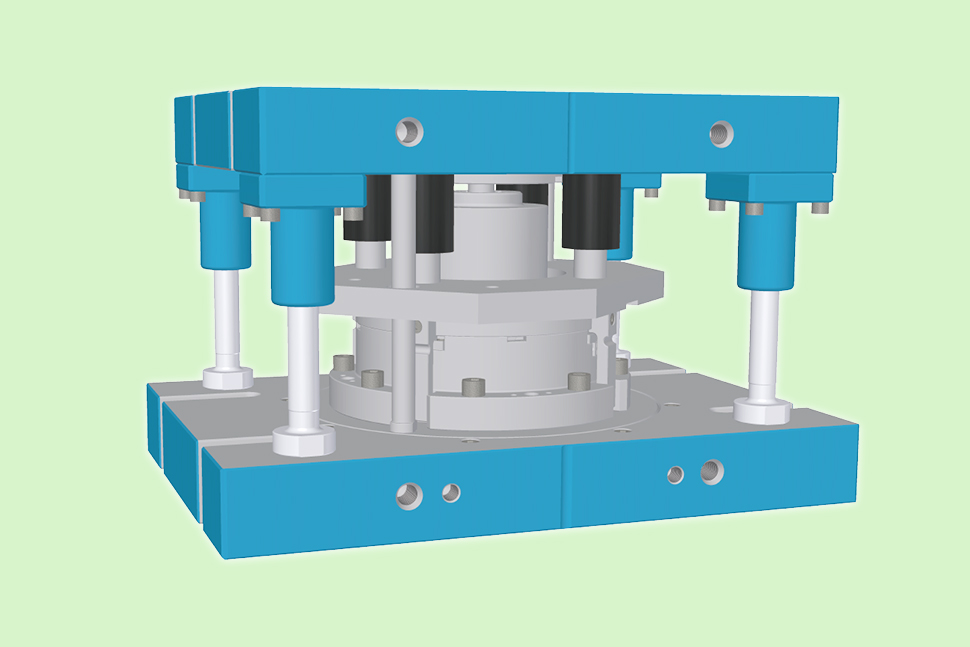

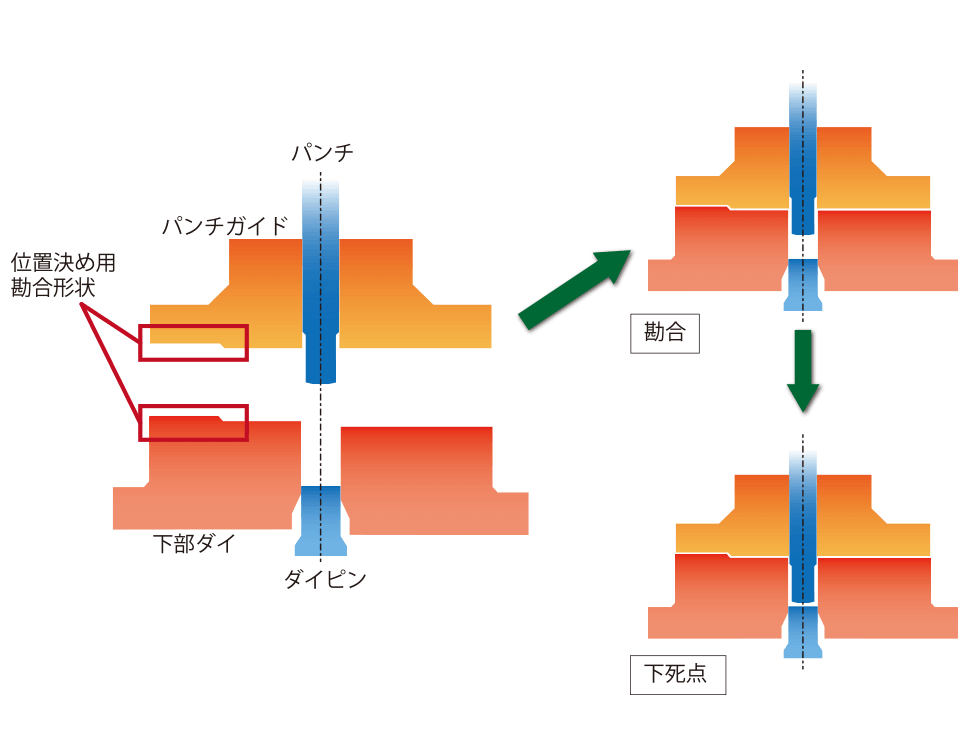

HIGH PRECISION DIE SET

Yamanaka Eng provide well-designed die set for the conventional press that achives high-precision forging.

Troubles that can be solved by "High Precision Die Set"

solutionDrastic Improvement of Tool Life

Stable Production

Improvement of Product Accuracy

Development of New Products having Functions for the Future

Features

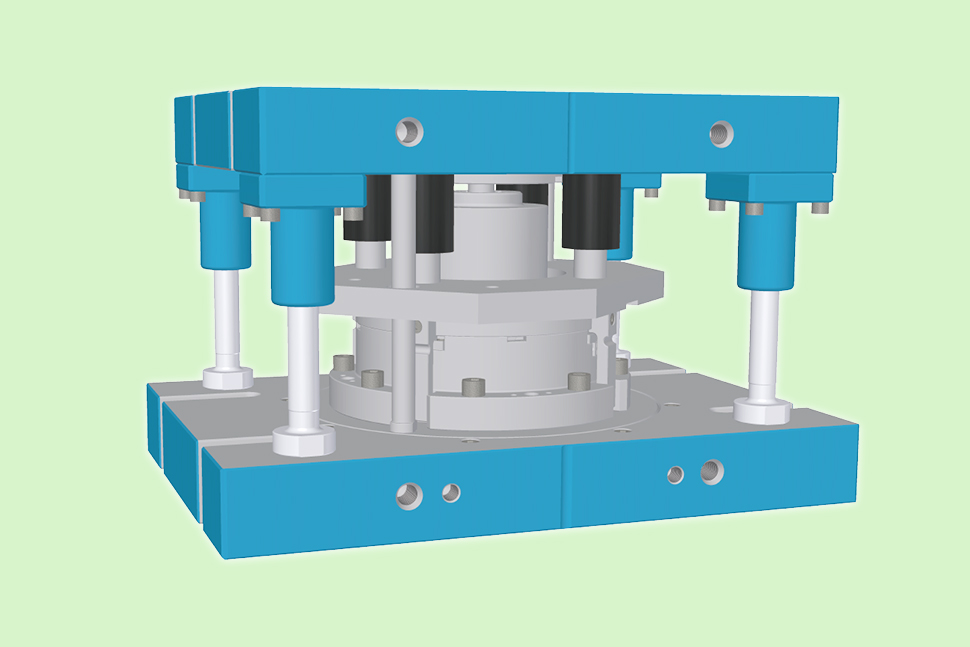

01

Reduces the influence of press slide tilting due to the lateral and rotary motion of the press. Only the axial component is transmitted to the punch.

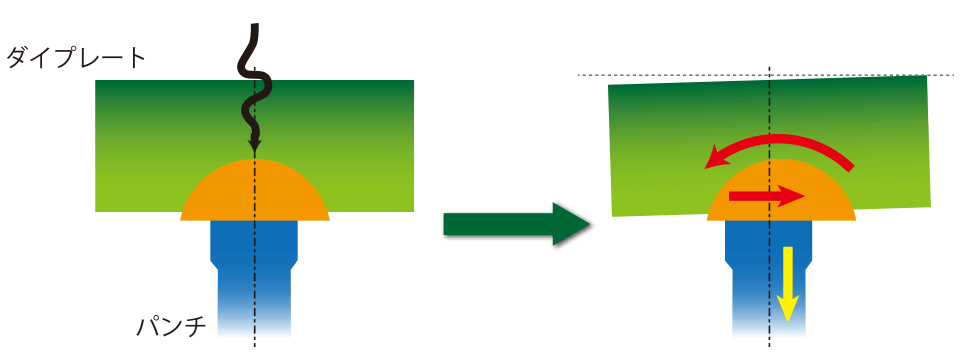

02

The accuracy is achieved by fitting the punch holder with the die holder. (Centering, vertical alignment)

In addition, the clearance between the punch and the punch holder is accurately controlled to reduce punch deflection and tilt, ensuring straightness of the punch.

Case Study

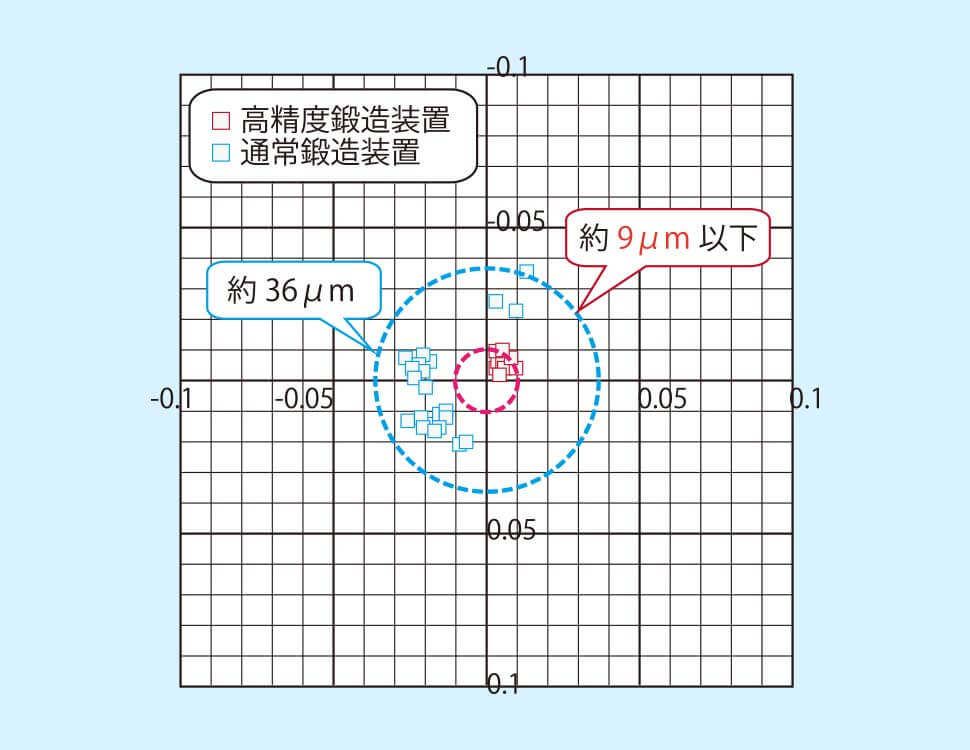

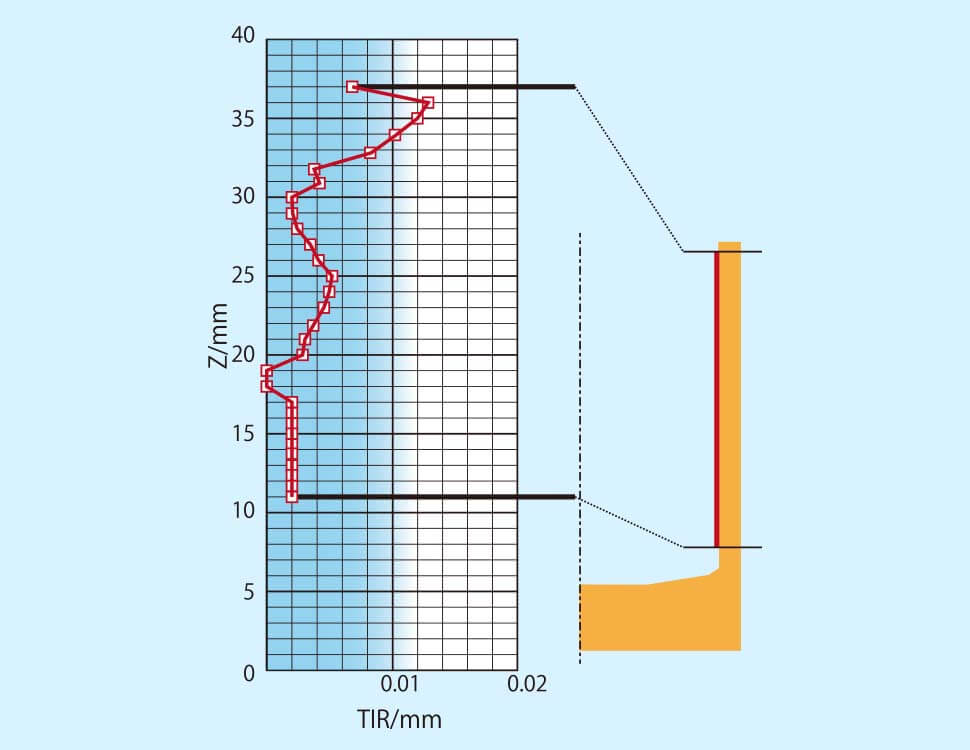

High precision forging mechanism is applied to backward extrusion forging of cup products by mechanical press.

Compared with products using a general die set, the variation in accuracy has been greatly reduced, and concentricity of 9 μm or less has been achieved.

Press Machine

- Mechanical Press

- Made in 1985

Significantly improved accuracy variation

Achieves concentricity of 9μm or less

Other parts (except cup tip)

Achieves TIR of 10μm or less

OTHER SERVICES

Yamanaka Eng is developing various business

Optimize the Production with Total Solution

Contact us if you have any question.