Contract Services

Contract Analysis

We provide services to help customers solve their problems,

such as design reviews, measures to prevent defects in forgings, and improvements in die life.

We provide support services to help our customers solve their problems. Experienced CAE engineers use simulation technology to meet customers' requests for various process simulations and condition settings.

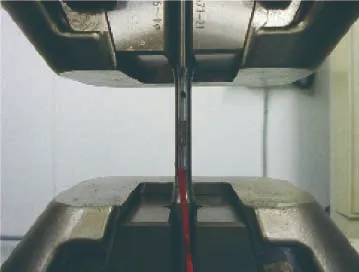

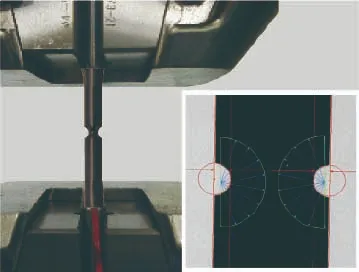

Contract Material Test

In CAE applications, material data has a significant impact on simulation results and is deeply related to simulation accuracy and reliability of simulation results.

We can respond to customers' requests to "acquire special material data that is not included in the DEFORM standard library" or "improve simulation accuracy by acquiring data on material used in actual machining".

Types of Material Test

-

Compression Test

-

Tension Test

(Bar and Plate) -

Notched Tension Test

(Ductile Fracture Test)

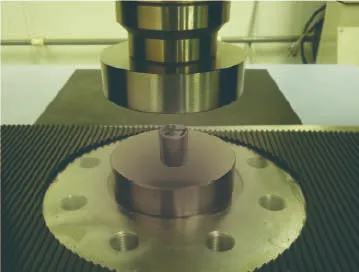

Compression Test Conditions

| Testing Equipment | Shimazu Autograph AG-X(max, load 25 t) |

|---|---|

| Test Conditions | Compression Speed:0.1mm/s(Average Strain Rate 0.01/s) Compression Ratio :Aimed at 70%(true strain of about 1.0) Test Temperature:Room Temperature Lubrication conditions:Teflon tape used Jig :Smooth die for compression test |

| Test Specimen | Diameterφ10、Height15mm(standard) -20mm→Quantity5pieces(2of them are spare) |

| Processing of Test Specimens | Possible (Materials must be prepared separately) |

| Load/Force and Displacement Measurement Method | Load:Load Cell Displacement:Crosshead displacement is measured(Deflection Compensation) |

| Delivery Time | From 2 weeks |

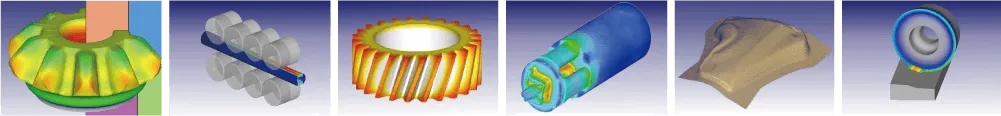

CAESOFT "DEFORM" is actively used in the following fields and situations.

-

Field

- Automobile

- Steel Industry

- Aerospace

- Electricity & Electronics

- Chemistry

- Railway

- Construction

- Heavy Machinery

- Medical

- Can Making

- Currency

- Precious Metals

-

Processing Process

- Cold/Warm/Hot Forging

- Powder Forming

- Sheet Metal Forming

- Thick plate Forming

- Press Forming

- Extrusion

- Rolling

- Joining/Calking

- Coining

- Heat Treatment

- Machining/Cutting

- Welding

- Additive Manufacturing

-

Prediction Technology

- Die life

- Product Dimensions

- Microstructures

- Stress/Strain

- Cracking

- Temperature

- Hardness

- Optimal Shape

Contact

Free demonstration/Quotation, etc

Please feel free to contact us.

Weekdays from 10:00 to 17:30

※We are distributing to Japan and ASEAN Southeast Asia.